Extruded tube aluminumheatingcoiled

Add to favorites

Compare this product

Characteristics

- Material

- aluminum

- Applications

- heating

- Other characteristics

- extruded, coiled

Description

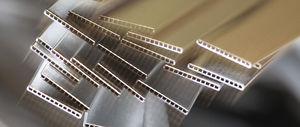

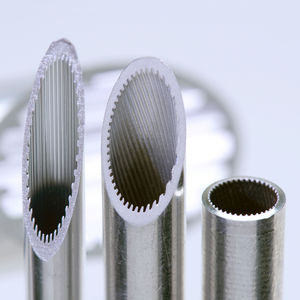

The extrusion process shapes aluminium by heating a billet and forcing it through a shaped opening in a die, producing up to five kilometers of extruded products from one aluminium billet.

After emerging from the extrusion process with the same shape as the die opening, the tubes are coiled. According to the product specification coatings like zinc, Hycot and flux can be applied, increasing the tubes’ performance.

Extruded tubes are manufactured with high precision and extremely low tolerance to meet the customer’s specific requirements.

Catalogs

No catalogs are available for this product.

See all of Hydro‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.