- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

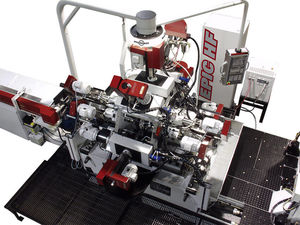

3-axis CNC machining center LSA 8-200vertical8 toolshigh-precision

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Number of tool stations

- 8 tools

- Other characteristics

- high-precision, high-rigidity, with linear motor, with turret

- X travel

60 mm

(2.36 in)- Y travel

60 mm

(2.36 in)- Z travel

180 mm

(7.09 in)- Rotational speed

6,300 rpm

(39,584 rad.min-1)- Power

8 kW

(10.88 hp)- Work feed X-axis

20 m/min

- Work feed Y-axis

20 m/min

- Work feed Z-axis

20 m/min

- Positioning accuracy

0.007 mm

(0.00028 in)

Description

The LSA 8-200 model has seven machining stations that feature 2-jaw chucks or custom fixtures for cast blanks. It also has one dedicated loading station and one station for gauging, inverting, or other special processes. It features four to six stations with six, eight or a maximum of ten horizontal units and two or three radial units. These can swivel and be adjusted, and thus are able to adapt to changing workpiece shapes.

The unique design of the LSA 8-200 is anchored by a robust frame weldment that is precision machined by the finest German craftsmen. It incorporates engineering and design excellence with the finest materials and components used in its creation. The results: a machining center of robust construction and exceptional accuracy.

The work envelope is a large 150mm x 100mm x 125mm. Part loading can be Flexible Manual or Robotic at the one dedicated loading station. One station is dedicated for gauging and special devices, and there are seven cutting stations featuring self centering two-jaw chucks, or the use of custom designed fixtures for complex castings.

The LSA design is a multi-way production cell with horizontal turret axis can be used to complement other rotary transfer automatic systems.

The machine application is based on the clamping position of the workpiece, flexibility required for the machine, access for setting up and the number of radial units.

The machine base exhibits high static and dynamic rigidity and allows excellent access to the workspace, as well as for the removal of chips.

The indexing unit is cycled between the machining stations with extreme accuracy and repeatability during the rotary transfer process.

Catalogs

LSA 8-200

4 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- Drilling CNC machining center

- Machining center for the automobile industry

- CNC machining center with rotary table

- 40 tools CNC machining center

- 4-axis CNC machining center

- CNC transfer machine

- Steel CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.