- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

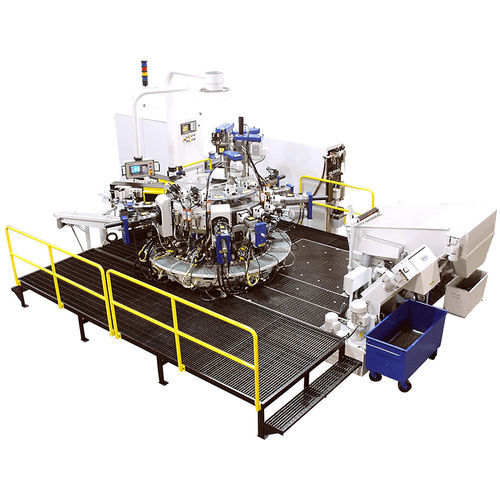

Rotary transfer machine HSNC8-position16-position

Add to favorites

Compare this product

Characteristics

- Type

- rotary

- Control type

- NC

- Number of positions

- 8-position, 16-position

- Other characteristics

- high-productivity, high-precision, horizontal-axis, vertical-axis

Description

The HS Indexing Chuck machine combines precision chucks with the indexing accuracy and reliability of the Hirth ring.

Available in 12 or 16 station models, the HS is fully integrated into the Hydromat product family, so the same modular components used in Hydromat's rotary transfer models are fully compatible with the HS machine,

This system is ideal for mid-to-high volume precision production of non-standard shaped castings or forgings, and is designed with the flexibility to easily accommodate families of parts.

Features

Extreme accuracy and reliability of a Hirth ring

Eliminates secondary operations

Several different unit sizes available

Coolant chiller optional

Hydromat Advantages Over Conventional Machining

Eliminates secondary operations

Extremely short remnants and thin cutoff for significant material saving

Reduces work in progress

Increased productivity due to bar change and quick changeover capabilities

Non-rotating bar stock provides quiet vibration free operation

Modular toolspindles with quick-change presettable heads for easy changeovers

Easily adapted for vertical machining requirements - up to 6 stations

Easily accessible operating controls and machine adjustments

Coolant and chips contained in the tooling area away from motors and controls

Precision table indexing and repeatability ensures accuracy with SPC to 2.0 CpK

Inverting unit repositions part for complete end to end machining

Catalogs

EPIC HS Indexing Chuck

4 Pages

EPIC HS 12 Indexing Chuck

4 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- Drilling CNC machining center

- Machining center for the automobile industry

- CNC machining center with rotary table

- 40 tools CNC machining center

- 4-axis CNC machining center

- CNC transfer machine

- Steel CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.