Worm gear reducer 030 ÷ 110right angleprecisionhigh-speed

Add to favorites

Compare this product

Characteristics

- Type

- worm

- Shaft orientation

- right angle

- Performance

- precision

- Applications

- industrial

Description

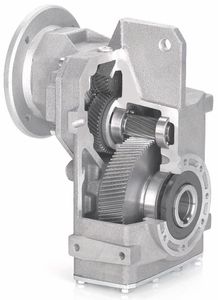

Anticorrosive worm gearboxes basic features

Single-piece aluminum alloy housing Is vacuum impregnated (MIL-STD 276) for protection and sealing. No secondary finish required but readily accepts paint. Combines light weight with high tensile strength. Precision machined for alignment of bearings and gearing.

Single piece alloy steel input shaft and worm shaft. High helix angle worm is case-hardened (Rc 58-60), ground, teeth are profiled and radiused, for noise reduction and enhanced efficiency.

Oversized bearings Support positively-retained, high speed shaft for higher shock load capacity - ideal for frequent starting and reversing application. Premium, Nitrile® high temperature seals each end.

Flange Fully modular to IEC and compact integrated motor. NEMA C flange.

Premium, high temperature Nitrile® output seals

Bronze alloy worm gears. Is centrifugally cast onto an iron hub for maximum strenght and superior life.

Oversize bearing For radial load capability and maximum hollow output shaft diameter.

Catalogs

ATEX

20 Pages

Rightangle wormboxes (metric)

56 Pages

Related Searches

- Right angle gearbox

- Precision gearbox

- Gear train gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Shaft gearbox

- Helical gear gearbox

- Low-noise gearbox

- Parallel-shaft gearbox

- Conveyor gearbox

- High-speed gearbox

- Shaft-mounted gearbox

- Custom gearbox

- Gearbox for marine applications

- Stainless steel gearbox

- Screw conveyor gear reducer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.