- Products

- Catalogs

- News & Trends

- Exhibitions

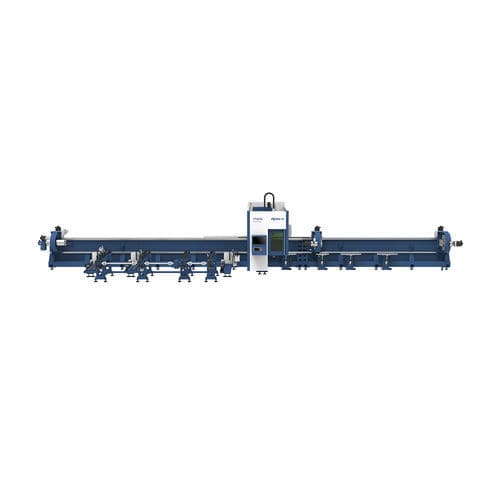

Fiber laser cutting machine TP seriesfor metalprofiletube

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- tube, profile

- Associated function

- bevel

- Configuration

- gantry type

- Other characteristics

- high-precision, high-efficiency, heavy-duty

- Tube diameter

Min.: 10 mm

(0 in)Max.: 560 mm

(22 in)- Laser power

Min.: 3,000 W

Max.: 20,000 W

- Overall length

16,000 mm, 20,000 mm, 26,000 mm

(630 in, 787 in, 1,024 in)- Overall width

4,000 mm, 5,000 mm

(157 in, 197 in)- Weight

1.2 kg, 2 kg, 300 kg, 500 kg

(1.32 lb, 2.2 lb, 661.39 lb, 1,102.31 lb)

Description

Hymson TP Series fiber laser cutting machine is specially design for heavy tubes and long tubes cutting.

• Equipped with three intelligent chucks for heavy tubes and profiles cutting.

• Minimum 0mm tailing for better material utilization.

• The brand new FSCUT professional pipe cutting system integrates multiple cutting functions.

• The product has rich optional accessories.

• Optional bevel cutting for seamless welding.

• It is your ideal production tool for high efficiency laser processing and pipe cutting.

Machine Structure

• The main body of the laser machine adopts the honeycomb welded structure and the internal stress is released through annealing treatment after welding.

• The guide surface is clamped and machined at a time using a large gantry type high precision processing center. The flatness and straightness of the guide surface are ≤0.05mm. The surface roughness is up to 0.8.

• Gantry beam structure to ensure high rigidity.

• Z-axis 2g follow-up acceleration, high efficiency.

• During the cutting process, the heavy-duty chuck holds the pipe material with three chuck jaws to provide multi-point support and correct pipe deformation.

• The shortest tail stock is 0mm, improving material utilization.

• Equipped with a clamping detection function to prevent accidental pipe falls and reduce the risk collision, improving safety.

• The rear chuck has intelligent exhaust function, which effectively reduces smoke and dust, and returns you to a clean workshop.

• It can process pipe weight up to 2T, pipe length up to 12000mm, round and square pipe range Φ20-560mm, support angle steel, channel steel, I-beam and other profiles.

VIDEO

Related Searches

- HYMSON cutting machine

- HYMSON metal cutting machine

- HYMSON CNC cutting machine

- HYMSON laser cutting machine

- HYMSON cutting machine for industrial applications

- Automatic cutting system

- HYMSON high-precision cutting machine

- HYMSON sheet metal cutting machine

- HYMSON high-speed cutting machine

- HYMSON fiber laser cutting machine

- HYMSON tube cutting machine

- Precision cutting system

- Aluminum cutting system

- HYMSON stainless steel cutting machine

- HYMSON high-performance cutting machine

- HYMSON high-efficiency cutting machine

- Compact cutting system

- Steel cutting system

- Bridge cutting system

- HYMSON carbon steel cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.