- Industrial machines and equipment

- Furnace and Heat Treatments

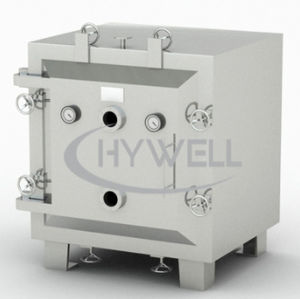

- Vacuum dryer

- Hywell Machinery Company

Vacuum dryer MDZaircleaningstatic

Add to favorites

Compare this product

Characteristics

- Technology

- vacuum

- Applications

- air

- Associated function

- cleaning

- Other characteristics

- static, cabinet

Description

Overview

The Intermittent supplemental air high-efficiency vacuum dryer is a new type of vacuum drying equipment designed and manufactured by our company to dissolve the following problems in the traditional vacuum drying oven during the drying process: the large temperature difference inside the oven, the slowly drying speed, the inconsistently dried of upper and lower materials are, and easy to foam and overflow drying tray during the drying process so that extends drying time . This low temperature drying equipment is mainly designed to drying for the materials with high sugar content, low temperature, easy to overflow, easy to foam, easy to oxidize. The equipment can use steam, hot water, electricity as the heat source, and it can complete the online cleaning or soak cleaning function. It has solved the problems of vacuum equipment of high energy consumption and low efficiency and disconnection from the pharmaceutical production process for many years. At present, it is a high-efficiency and energy-saving replacement product with drying and cleaning functions.

Principle

The equipment have heat function of the inner layer board and cabinet jacket under the vacuum condition to drying the materials. The vacuum pump is used for suction and dehumidification to make the working chamber form a vacuum state and reduce the boiling point of water. It can obtain a high drying rate at a low temperature, and the heat is fully utilized. There is no impurity in the drying process. The equipment is static vacuum drying, so it will not cause damage to the shape of the dried material.

Catalogs

No catalogs are available for this product.

See all of Hywell Machinery Company‘s catalogsRelated Searches

- Furnace

- Electric furnace

- Heat treatment furnace

- Drying system

- Drying furnace

- In-line dryer

- Baking oven

- Automatic furnace

- Air blast drying system

- Air circulating furnace

- Thermal furnace

- Batch dewatering system

- Centrifugal dewatering system

- Hot air drying system

- Vacuum drying system

- Hot air furnace

- Drying system with belt conveyor

- Cleaning dewatering system

- Compact drying system

- Stainless steel drying system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.