- Industrial machines and equipment

- Mixing and Dosing

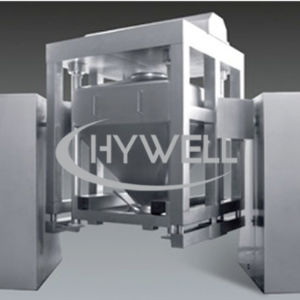

- Powder mixer

- Hywell Machinery Company

Powder mixer V typevacuumcompactrotary

Add to favorites

Compare this product

Characteristics

- Product type

- powder

- Other characteristics

- vacuum, compact, rotary, manual

- Capacity

Min.: 40 l

(10.57 gal)Max.: 1,200 l

(317.01 gal)

Description

Principle

There is one set of motor and reducer at one end of the spiral mixer machine. The motor and reduce are connected by belts. When the power on, the motor start work to drive reducer work ,The reducer rotate with the coupling to make the barrel rotary continuously, drive material inside the barrel runs up, down, left, right to reach uniform mixing .

Features

1. This machine is our widely absorbing, digesting foreign advanced technology, combined with the new type conditions of successful research and development. Reasonable structure, stable performance, convenient operation.

2. To ensure the quality of the machine, we adopt high quality out purchased parts for this machine.

3. Equipped with fine manufactured hopper that fully meet the requirements of GMP, no residues of discharge, and it's easy for cleaning or washing

4. The whole machine features novel design, compact structure, and good appearance, the evenness of mixing reaches 99% , and the volume charge factor reaches 0.6

5 Smooth running, reliable performance, easy operation.

6. Control system has more choices, such as push button , HMI+PLC and so on.

7. The feeding system for this mixer can be by manual or vacuum feeder or screw feeder and so on

8. Machine materials : AISISUS304 , AISISUS316L, and other material .

Application

The mixed powder is suitable for the good flow material, little difference in physical properties of the mixture, and the degree requirements is not high and short mixing time of material mixing, due to material V type mixing container flows smoothly, does not damage the material type, it is widely used in pharmaceutical, chemical, food industry etc

Catalogs

No catalogs are available for this product.

See all of Hywell Machinery Company‘s catalogsRelated Searches

- Dynamic homogenizer

- Batch homogenizer

- Grinding mill

- Solid blender

- Vertical agitator

- Stainless steel agitator

- Agitator for the chemical industry

- Horizontal grinding mill

- Powder blender

- Horizontal blender

- Paddle blender

- Compact agitator

- High-speed homogenizer

- Vacuum homogenizer

- Automatic homogenizer

- Stainless steel grinding mill

- Ribbon blender

- Adhesive agitator

- Centrifugal grinding mill

- Rotary blender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.