- Industrial machines and equipment

- Furnace and Heat Treatments

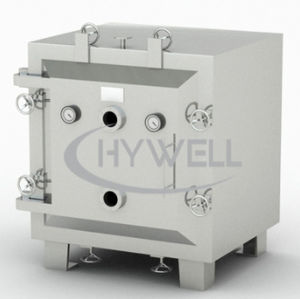

- Hot air dryer

- Hywell Machinery Company

Hot air dryer DWbatchgasfeeder

Add to favorites

Compare this product

Characteristics

- Technology

- hot air

- Batch/continuous

- batch

- Applications

- gas

- Associated function

- feeder

- Other characteristics

- with belt conveyor, stainless steel

Description

Principles

The materials are uniformly distributed on the mesh-belt by the material feeder. The mesh-belt generally adopts 12-60 mesh stainless steel mesh and it is drawn by a transmission device and move inside the dryer. The dryer is composed of several sections. For each section, the hot air is circulated separately. Part of exhausted gas is exhausted by a special moisture elimination blower. The waste gas is controlled by an adjustment valve. The hot air passes through the mesh-belt covered with bring water material away. The mesh-belt moves slowly, running speed can be freely adjusted according to the material collector continuously. The top and low circulation units can be freely equipped according to the users requirements. The number of section might be selected according to the production demands.

Machine structures

1. Inlet air system

The inlet air system consists of Primary filter, middle efficiency filter, high efficiency filter (Optional) and heater with accurate temperature control. The inlet air flow, speed and pressure is variable and controllable. For the heater , it can be steam radiator ,electrical heater , gas furnace and so on .

2. Main Machine Structure

mesh-belt generally adopts 12-60 mesh stainless steel mesh and it is drawn by a transmission device The main body structure consists of mesh-belt, belt transmission device , heater, exhaust fan.

3. Exhaust sir system

The exhaust dust collection filter is optionally designed for protect environment.

Catalogs

No catalogs are available for this product.

See all of Hywell Machinery Company‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.