- Industrial machines and equipment

- Furnace and Heat Treatments

- Hot air dryer

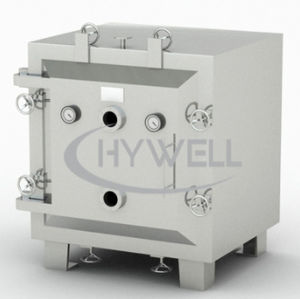

- Hywell Machinery Company

Fluidized bed dryer ZLGhot airgasair

Add to favorites

Compare this product

Characteristics

- Technology

- fluidized bed, hot air

- Applications

- gas, air

- Other characteristics

- vibrating, static

Description

Principle

Fluid bed dryer is a new technology developed on the basis of static fluidized bed. Mechanical vibration is added on the static fluidized bed. The material has been feed into the machine from the front of machine, Fresh air through filtering and heating is sent to the bottom of fluidized-bed by fan and contacts with solid raw material on vibration bed plate. under the dual function of the vibration and air flow, the materials move along the fluidized bed as throwing forward continuously. In this way the heat exchange between air and solid is carried out. The dried raw material is discharged from outlet and wasted gas is exhausted from the top of fluidized-bed where catches solid powder through cyclone separator ,The heating way have different kinds to choice such as steam, electricity or hot air furnace can be used (it can be supplied as client request ).

Features

1. The state of fluidization is uniform, with no dead angle and blown through phenomenon.

2. It is good in regulation and wide in suitability. The moving speed and the bed depth of the material in the dryer can achieve stepless adjustment by the changes of the amplitude.

3.It makes small damage to the surface of the material, can be used for the drying of the fragile materials and will not affect the work results if the particles are irregular.

4.Materials have been heated evenly, full exchanged the heat. It is a process of large intensity of drying.

Catalogs

No catalogs are available for this product.

See all of Hywell Machinery Company‘s catalogsRelated Searches

- Furnace

- Electric furnace

- Heat treatment furnace

- Drying system

- Drying furnace

- In-line dryer

- Baking oven

- Automatic furnace

- Air blast drying system

- Air circulating furnace

- Thermal furnace

- Batch dewatering system

- Centrifugal dewatering system

- Hot air drying system

- Vacuum drying system

- Hot air furnace

- Drying system with belt conveyor

- Cleaning dewatering system

- Compact drying system

- Stainless steel drying system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.