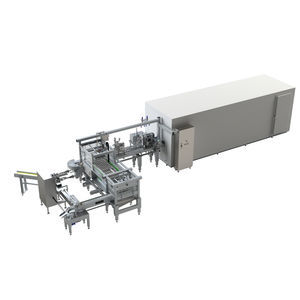

Stainless steel working table W series for the food industry

Add to favorites

Compare this product

Characteristics

- Options

- stainless steel, for the food industry

Description

W1/W2 are flexible independent attachments to extrusion lines, capable of producing of wide range of inovative, sophisticated products

Capacity from 6 000 pcs/h (1 row of products) to 21 000 pcs/h (3 rows of products).

• conveyor with belt speed regulation, product transfer unit, pneumatically operated

• PLC unit to synchronize the worktable with extrusion line, incl. encoder

• cutting station, heated, temperature control

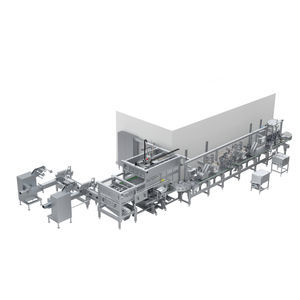

Dynamic stick inserter:

• Gentle inserting at sync movement

• Pneumatic or servo synchronisation

• 2-3-4 wide stick inserters

Transfer and cutting station:

• Pneumatic transfer unit

• Cutting station with heated blade

• Easy adjustable

Multilayer extrusion station:

• 4-8 extruders for miltulayer products

• 2-4 chocolate sprayers

• Heated choco vat

W2 rotary head:

• 2 rotary heads

• 3 colours ( 1 x central + 2 x rotary colours)

• Ice cream/water ice combination

VIDEO

Catalogs

W1/W2

4 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.