- Products

- Catalogs

- News & Trends

- Exhibitions

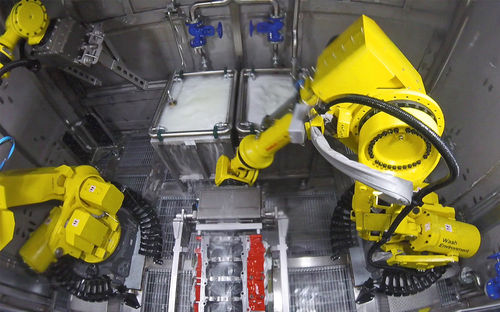

Robotic washing system waterautomaticautomotive

Add to favorites

Compare this product

Characteristics

- Technology

- water

- Operational mode

- automatic

- Applications

- industrial, process, automotive, for the aerospace industry

- Other characteristics

- robotic

Description

The robotic washing system is designed to offer maximum flexibility and versatility in the handling and handling of the elements to be treated. Thanks to the use of anthropomorphic robots, it is possible to perform various washing operations in a precise and controlled way.

This type of system allows you to manipulate the element to be treated using a robotic arm, which is capable of performing multi-axis movements and positioning the element with millimeter precision. Alternatively, a suitable tool can be mounted on the robot’s wrist to treat the item specifically.

The use of robots offers numerous advantages in the field of industrial washing. First of all, robots make it possible to effectively manage different types of elements, easily adapting to their specific shapes, sizes and characteristics. This makes it possible to address a wide range of applications and to deal with elements of various complexities.

The use of robots in a washing plant also makes it possible to optimize the efficiency of the process. Cycle times can be reduced thanks to the speed and rapidity of robot operations, allowing for an increase in overall productivity . Furthermore, the robots can be integrated with artificial vision systems for the automatic recognition and inspection of the elements, further improving the efficiency and quality of the washing process.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.