- Products

- Catalogs

- News & Trends

- Exhibitions

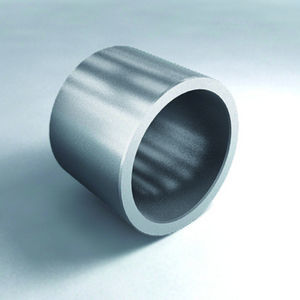

Open plain bearing IB013bronzesintered bronzePTFE

Add to favorites

Compare this product

Characteristics

- Type

- open

- Material

- bronze, sintered bronze, PTFE

- Other characteristics

- self-lubricating, wear-resistant, dry

Description

Bronze ( CuSn8P ) +

Bronze ( CuSn8Zn3 ) +

PTFE + Fillers

Introduction

Dry bearings(bronze/red PTFE), made of tin bronze as base material, are produced by the process of being sintered bronze powder as medium layer and coated PTFE as lubrication layer. They are in conformity with the European RoHS environmental protection standards and widely used in the applications of automotive, bicycle , hydraulic transmission, metallurgy and casting due to the advantages of lead free, low friction coefficient, good self-lubricating, good wear resistance and good thermal conductivity.

Physical and Mechanical Properties

thermal conductivity λ

60 W/mK

max. operating temperature Tmax

+280 ℃

min. operating temperature Tmin

-200 ℃

compressive yield strength δc

300 N/mm

max. static load Psta,max

140 N/mm

max. dynamic load Pdyn,max

140 N/mm

max. sliding speed v-oil lubricated

5.0 m/s

max. sliding speed v-dry

2.5 m/s

max. PV factor-dry

1.0 N/mm2·m/s

max. PV factor- oil lubricated

10.0 N/mm2·m/s

coefficient of friction f-dry

0.04-0.25

coefficient of friction f-oil lubricated

0.02-0.08

shaft surface finish Ra-dry

0.4±0.1 µm

shaft hardness

>200HB

Related Searches

- Plain bearing

- Bearing unit

- Metal plain bearing

- Metal bearing unit

- Self-lubricating plain bearing

- Linear bearing

- Polymer plain bearing

- Linear ball bearing

- Cylindrical plain bearing

- Steel plain bearing

- Bronze plain bearing

- Spherical plain bearing

- Ball bearing bearing unit

- PTFE plain bearing

- Composite material plain bearing

- Heavy load plain bearing

- Wear-resistant plain bearing

- Steel linear bearing

- Corrosion-resistant plain bearing

- Lube-free plain bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.