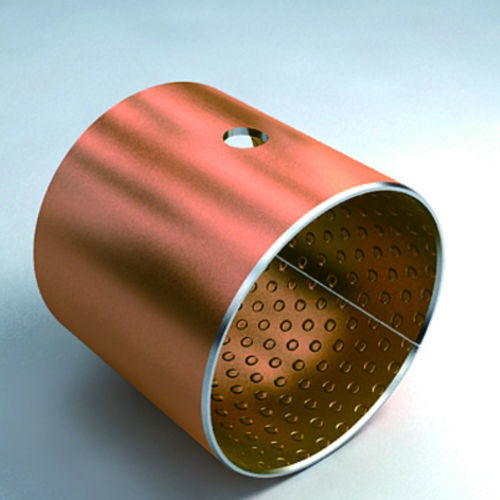

Material

Steel ( DIN-St12|ASTM-A366/A366M-97|JIS-SPCC ) +

Bronze ( DIN-CuPb10Sn10|SAE-797|JIS-LBC3 ) +

Graphite

Bronze Hardness 70HB-100HB

Introduction

Bimetallic bearings(CuPb10Sn10/graphite), made of low carbon steel as base material, are produced by the process of being sintered tin bronze CuPb10Sn10 powder as layer and rolled diamond oil pockets on the surface of alloy layer for storing graphite. They are widely used in the applications of automotive, truck, hydraulic transmission and engineering machinery due to the advantages of low friction coefficient, good self-lubricating and good load capacity.

Physical and Mechanical Properties

max. operating temperature Tmax-greased

+150 ℃

max. operating temperature Tmax-oil lubricated

+250 ℃

min. operating temperature Tmin

-40 ℃

max. static load Psta,max

300 N/mm

max. dynamic load Pdyn,max

140 N/mm

max. sliding speed v-greased

2.5 m/s

max. PV factor-greased

2.8 N/mm2·m/s

coefficient of friction f-greased

0.05-0.12

coefficient of friction f-oil lubricated

0.04-0.12

shaft surface finish Ra

≤0.8 µm

shaft hardness-normal

>200HB

shaft hardness-for service life>2000 hours

>350HB