- Products

- Catalogs

- News & Trends

- Exhibitions

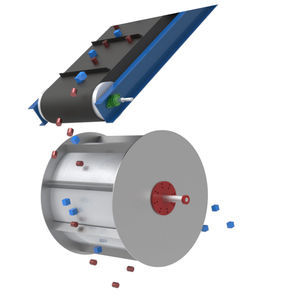

Magnetic pulley for belt conveyorsmetalhorizontal

Add to favorites

Compare this product

Characteristics

- Type

- magnetic

- Applications

- for belt conveyors

- Material

- metal

- Other characteristics

- horizontal

Description

The magnetic pulleys are a highly efficient separation system to eliminate ferric contamination from many different materials as aggregates, granulated plastics, urban waste, etc. They are especially suitable for continuous work in demanding environments.

The magnetic pulleys are installed at the discharge end of the conveyor belt.

They can be installed as a drive unit or rotate by the action of the conveyor belt. For better traction, the magnetic pulley can be optionally coated with PVC rubber to get further toughness of the belt. They are manufactured in a multitude of sizes, with a large range of diameters and lengths. The central axis is designed according to customer requirements and can be welded or removable using clamping bushings.

This equipment requires minimal maintenance. The magnetic part can be composed of neodymium or ferrite magnets in different configurations, depending on each installation case.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.