- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Position detector arcweld seamprocess

Add to favorites

Compare this product

Characteristics

- Detected entity

- position, arc, weld seam

- Application

- process

- Other characteristics

- combination

Description

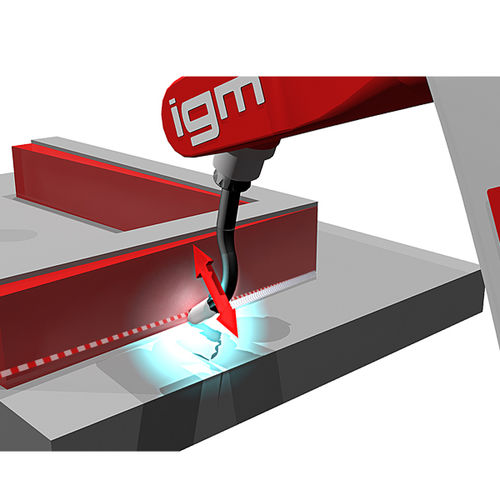

ARC SEAM SENSING - PRECISION WELDING OF FILLET AND V-SEAMS

During the welding process arc seam sensing is used to compensate for positional tolerances of the welding seam.

By means of a special software and specifically designed hardware, the "actual" seam position of fillets and V-shaped joints is computed by processing data measured, while arc weaving gives a corresponding shift of the original programmed point(s) to the true seam position. This arc seam sensing technique can be used with a complete range of welding transfers such as short arc, spray arc and pulsed arc welding - using single or Tandem applications. The welding torch then follows the path of the seam joint exactly.

This process can be advantageous in combination with gas nozzle sensing. There, the starting point of each welding seam is detected by the sensor and the arc is ignited at the correct position with the desired stick-out.

igm is providing turn-key robotic welding solutions tailored to the customers needs and products.

No single components are sold.

Catalogs

No catalogs are available for this product.

See all of igm Robotersysteme AG‘s catalogsRelated Searches

- Position transducer

- Non-contact position transducer

- Industrial position sensor

- Process detector

- Precision position sensor

- Rugged position transducer

- Digital output position sensor

- High-precision position sensor

- Combination detector

- Robotic position sensor

- Economical position sensor

- Resistance position sensor

- PSD detector

- Flexible position sensor

- EtherCAT position sensor

- Position sensor for welding applications

- Weld seam detector

- Arc detector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.