- Products

- Catalogs

- News & Trends

- Exhibitions

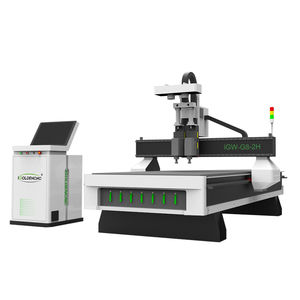

5-axis CNC machining center iGW-5Averticalwith moving tablechamfering

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- with moving table

- Associated functions

- chamfering, cutting, drilling

- Applications

- for medical applications, for the aerospace industry

- Other characteristics

- high-precision

Description

5 axis cnc machining is called a 5-axis machine because it has five axes of movement that can be controlled simultaneously, allowing it to cut and shape parts from multiple angles and directions.By using a 5-axis machine, manufacturers can produce complex parts in a single setup, which can reduce production time and increase accuracy.

The 5-axis linkage machining center is a kind of mechanical equipment with high scientific and technological content and high precision, and the whole machine adopts high-quality components. Can achieve a variety of complex, heavy processing. Using mobile table structure, large flexibility, wide processing range. Good at space surface processing, shaped processing, hollow processing, punching, oblique drilling, chamfering, etc., working speed, traveling speed, cutting speed can be controlled separately, greatly improving productivity.

Widely used in aerospace, military scientific research, precision machinery, high-precision medical equipment, normal manufacturing and other fields.

It offers simultaneous control of five axes of motion, allowing for versatile and precise machining of a wide range of materials.

5 Axis CNC Machine Application:

Composite materials industry: trimming and perforating various composite materials such as plastic parts, glass steel parts, rubber and plastic products.

Mold industry: five-axis processing of glass fiber reinforced plastic wooden molds, cast wooden molds, resin products, clay models, and various non-metallic molds.

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- CNC router

- 3-axis router

- Wood router

- Drilling machine

- Milling CNC machining center

- Cutting CNC machining center

- Milling machine

- Spindle router

- Drilling CNC machining center

- 3-axis milling machine

- CNC drilling machine

- Vertical milling machine

- Plastic router

- CNC machining center with moving table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.