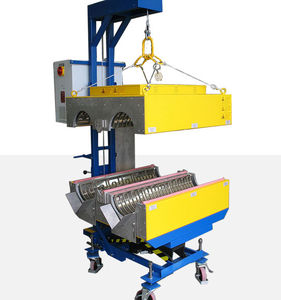

Chamber oven 1361482drying

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- drying

- Maximum temperature

120 °C, 150 °C, 220 °C, 300 °C

(248 °F, 302 °F, 428 °F, 572 °F)- Width

300 mm, 1,200 mm, 3,000 mm

(11.81 in, 47.24 in, 118.11 in)- Height

950 mm, 1,220 mm, 1,600 mm

(37.4 in, 48.03 in, 62.99 in)- Depth

600 mm, 750 mm, 2,100 mm

(23.62 in, 29.53 in, 82.68 in)

Description

As single- or multi-chamber oven the drawer ovens offer a high variability. Matched to the size of to be dried material and drying temperature these ovens are following the demands of the customers. Bashing plates on single drawers avoid the escape of warm air out of the dryer with extracted drawers. Synthetic plates (2,000 x 2,900 mm) can be put and preheated on the teflon-coated drawers. These drawers in combination with base units offer an un-resistant extraction of the material. The material is easily to extract. The drying times are indicated via single time relays. The process is indicated by visual and acoustic signals for each drawer. The start of the drying time occurs with a micro switch automatically. It is as well possible to interlock single drawers that a premature extract is not possible. Dryers with linear bearings are used e.g. within tyre production. The loading is manual or with an indoor crane.

Options

voltage and wattage variations

operating temperature variations

painting, multi-colour available as per customer request

labelling and documentation in various languages

galvanized, hot-dip aluminized steel plate or stainless steel internal tank

stainless steel or aluminium drawers

perforated steel plate drawer bottom available (square or round punching)

electronic PID temperature control with load circuit contactor or solid state relay

temperature control with self-improvement function, process alarm for further processing available

multi-tank oven

doors on front and back side

Catalogs

No catalogs are available for this product.

See all of Ihne & Tesch GmbH‘s catalogsOther Ihne & Tesch GmbH products

Industrial Oven Systems and Pre-Heat devices

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying system

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- Air blast drying system

- Digital furnace

- Continuous furnace

- Annealing furnace

- Thermal furnace

- Hot air drying system

- Vertical furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.