Cabinet oven 1357098electricdigital

Add to favorites

Compare this product

Characteristics

- Configuration

- cabinet

- Heat source

- electric

- Other characteristics

- digital

- Maximum temperature

100 °C, 350 °C

(212 °F, 662 °F)- Width

Min.: 480 mm

(18.9 in)Max.: 4,700 mm

(185.04 in)- Height

Min.: 330 mm

(12.99 in)Max.: 800 mm

(31.5 in)- Depth

Min.: 480 mm

(18.9 in)Max.: 1,050 mm

(41.34 in)

Description

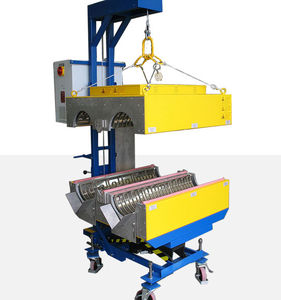

When extraction of the dry material is only to handle from above, e.g. heavy, bulky tools Chest Ovens find their application. Our Chest Ovens offer the possibility with simple pulley cover openings and protected integral tension springs. The opening of smaller devices is supported with gas springs.

Options

voltage and wattage variations

operating temperature variations

painting, multi-colour available as per customer request

labelling and documentation in various languages

falvanized, hot-dip aluminized steel plate or stainless steel internal tank

massive and stable steel plate or stainless steel supporting shelves for heavy loading material

electronic PID temperature control with load circuit contactor or solid state relay

temperature control with self-improvement function, process alarm for further processing available

multi-tank oven

electronic digital clock timer

operating hours counte

timer function, turns on after adjusted time (max 99h 59 min) (on request as well off)

program controller with up to 20 programs each with 16 segments

signal and warning light as per requested function

shutter plates at air-entering side for subsequent temperature improvement

multichannel diagram writer for documentation of temperature process

interfaces as per customer specification

Catalogs

No catalogs are available for this product.

See all of Ihne & Tesch GmbH‘s catalogsOther Ihne & Tesch GmbH products

Industrial Oven Systems and Pre-Heat devices

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying system

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Tunnel furnace

- Baking oven

- Industrial furnace

- Air blast drying system

- Digital furnace

- Continuous furnace

- Annealing furnace

- Thermal furnace

- Hot air drying system

- Vertical furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.