- Metrology - Laboratory

- Optical Component

- Pulsed laser

- II-VI INFRARED

Pulsed laser infraredNd:YAG

Add to favorites

Compare this product

Characteristics

- Operational mode

- pulsed

- Spectrum

- infrared

- Other characteristics

- Nd:YAG

- Power

5,000 W

(6.798 hp)- Wavelength

1.1 µm

Description

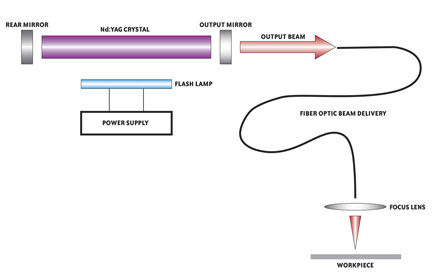

Lasing materials of solid-state lasers are synthetic crystal rods. The rods are pumped with energy, typically from xenon flash lamps or laser diode stacks. Most solid-state lasers use resonator cavities with external mirrors. For industrial applications, the most commonly used laser crystals are made of Nd:YAG. These lasers operate in the near-infrared at a wavelength of 1.06 μm. Power output can be as high as 5 kilowatts. The uses of Nd:YAG lasers include cutting, drilling, welding, scribing, and engraving. Materials processed by Nd:YAG lasers include carbon resin, ceramics, most metals, and most plastics. YAG lasers often are used in industrial welding applications and are power-scaled by placing rods in series. Unlike CO2 systems, YAG lasers can deliver power via a fiber delivery system. While the output fiber (and beam diameter) is larger than with a fiber laser, they still offer more flexible beam delivery than CO2 lasers. Indeed, fiber delivery at high power levels has permitted the Nd:YAG into areas where there is limited overlap with CO2. Integration is also easier than with CO2 lasers because the fiber can be used with robots. Consequently, primary advantages to the YAG are lower wavelength and the ability to use robotics. In addition, YAGs have a low plasma plume and, therefore, require no shield gas. Disadvantages to this type of laser include poor wall plug efficiency of approximately 3 percent and a large footprint (relative to diode and fiber laser systems). This larger footprint is due to its large cooling system. YAGs also have adequate beam quality for welding but not for cutting (since the achievable energy density is lower).

Catalogs

No catalogs are available for this product.

See all of II-VI INFRARED‘s catalogsRelated Searches

- Pulsed laser

- Glass lens element

- Fiber optic laser

- Optical prism

- Spectrum lens element

- Optical window

- Glass optical prism

- Visible lens element

- Round mirror

- BK7 lens element

- Convex array lens element

- Crystal lens element

- Infrared laser

- Spherical lens element

- Laser mirror

- Cylindrical lens element

- Plano-convex lens element

- Anti-reflective lens element

- Polarizer

- Infrared lens element

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.