- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Diameter measuring instrument VCPEx+digitalopticalcamera

Add to favorites

Compare this product

Characteristics

- Measured value

- diameter

- Technology

- digital, optical, camera

- Applications

- industrial, laboratory, process, calibration, inspection, extruder nozzle

- Configuration

- portable, benchtop, compact, mobile

- Other characteristics

- stand-alone, automatic, with display, high-precision, USB, adjustable, graphic display, high-speed, with integrated screen, all-in-one, low-noise

Description

Camera-based system for measuring wire quides and extrusion tools mean that only independently tested tools without user influence are used within the production process. It is specially designed for use in production, the tool handout and the laboratory.

Possible measurement results:

■ Maximum, minimum and average inside diameter

(With these values any deformation or wear can be identified - the wires could be positioned undefined in the cable after extrusion which can lead to an underranged wall thickness.)

Device details:

■ Fast, reliable and highly accurate measuring process

■ Telecentric cameras and lighting guarantee exact measurement results

■ Up to 2 cameras and measuring fields in one compact device

■ Simple handling and positioning of the extrusion tools (including conical tools / conical wire guides)

■ Focus indicator for easy focus adjustment

■ No extraneous light influences thanks to measuring within a closed housing

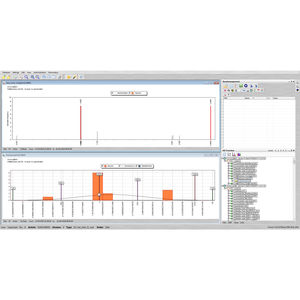

■ VeloxExtrusion measurement software included

■ Robust and compact design, easy to handle

VIDEO

Catalogs

Related Searches

- Measuring device

- Measuring machine

- Digital measuring device

- Portable measuring device

- Optical measuring machine

- Automatic measuring machine

- Industrial gauge

- Manual test kit

- High-precision measuring machine

- Industrial test equipment

- Measuring system for industrial applications

- Portable test kit

- Automatic measuring device

- Benchtop measuring device

- Compact measuring device

- Measuring device with display

- Distance measuring machine

- Control measuring machine

- Laboratory measuring device

- High-precision measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.