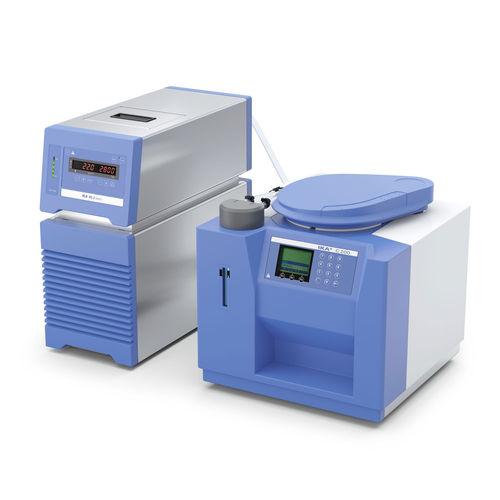

The C 200 h auto package allows operating the C 200 with a completely automated water cycle. This results in ease of handling and saves valuable time especially for laboratories with a low number of analyses. The water circulates in a closed loop and is kept at a constant temperature by using a recirculating chiller. This leads to shorter preparation time for each experiment and even better reproducible results.

The scope of delivery includes:

C 200 calorimeter measuring cell

C 5012 halogen resistant, catalytic activated decomposition vessel

C 200.2 conversion kit for C 5012

C 248 oxygen filling station

RC 2 basic circulating chiller

C 200.RC hose set

Consumables for calibration and installation

The semi-automated and conforming-to-standards combustion calorimeter determines the gross calorific value of liquid and solid samples. So far it has mainly been used for teaching and training purposes at technical schools and universities. Due to the automated water handling it is now also suitable for industrial laboratories with low number of analyses.

The catalytic activated, halogen resistant decomposition vessel C 5012 is specifically designed for the combustion of samples that contain halogens and sulfur ( > 3 % ). The material of the decomposition vessel (Hastelloy) prevents corrosion caused by samples with high chlorine content. The catalytic activated inner-surface leads to higher recovery rates in case analysis of halogens and/or sulfur is required after the combustion.

Four different operation modes enable the user to control the measuring times according to individual requirements:

Isoperibol: approx: 17 min.

Dynamic: approx. 8 min

Manual: approx.