- Power Transmission - Mechanical components

- Bearing and Linear Guide

- Ball bearing linear guide

- IKO Nippon Thompson Europe

- Products

- Catalogs

- News & Trends

- Exhibitions

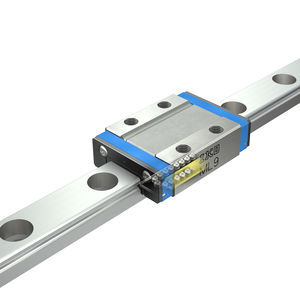

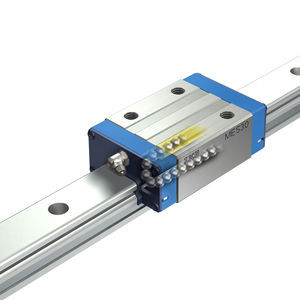

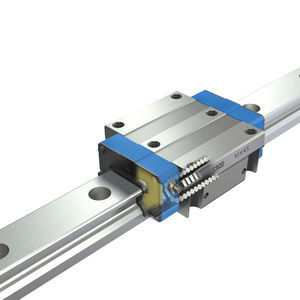

Slide linear guide LWE seriesball bearingstainless steelcompact

Add to favorites

Compare this product

Characteristics

- Technology

- slide, ball bearing

- Other characteristics

- stainless steel, compact, high-rigidity, track, flange, for medical equipment

Description

Linear Way E is a linear motion rolling guide with a compact slide unit that provides endless linear motion over a track rail. Two rows of steel balls come in contact with the raceway surface at four points, enabling stable accuracy and rigidity, even in applications where loads have variable direction and size, or complex loads are applied. This compact, highly versatile universal series is available in many shapes and sizes.

Interchange specifications are available. Since the slide unit and track rail dimensions are separate, each can be individually added or exchanged.

Lower, narrower, shorter...more compact in every aspect.

Slide units include two flange types with different mounting directions and three narrow block types.

Available types include: a short type, with the same cross-section as the standard type, and a high-rigidity long type.

Stainless steel types, with excellent corrosion resistance, are also available. They are ideal for use in clean rooms for medical equipment, various disc readers and semiconductor manufacturing devices.

The Low Decibel Linear Way E is a linear motion rolling guide optimally designed based on thorough analysis of steel ball re-circulation behavior and sound quality analysis. Due to a resin separator built-in between the balls, direct contact is eliminated and smooth and quiet motion is achieved. Especially in manufacturing machinery that uses several linear motion rolling guides, they can reduce the noise level in the factory, contributing to a better work environment for the employees.

By incorporating a resin separator that prevents direct contact between the steel balls, smooth and quiet motion is realized.

Catalogs

Linear Motion Guide Series

392 Pages

Other IKO Nippon Thompson Europe products

Linear Motion Rolling Guides

Related Searches

- Rolling bearing

- Steel bearing

- Roller bearing

- Radial rolling bearing

- Linear motion system

- Axial rolling bearing

- Single-row bearing

- Double-row bearing

- Steel linear guide

- Rod end

- Ball bearing linear motion system

- Cylindrical roller rolling bearing

- Slide linear motion system

- Cage assembly bearing

- Compact linear motion system

- High-speed bearing

- Linear bearing

- Stainless steel rolling bearing

- Linear ball bearing

- Track linear motion system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.