Fuel additive Aurora™

Add to favorites

Compare this product

Characteristics

- Applications

- for fuel

Description

Protect the lifespan and performance of your furnace or boiler

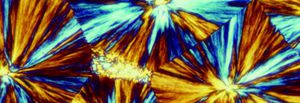

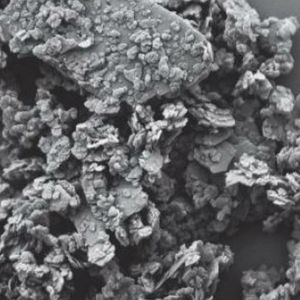

Our Aurora range is a patented combustion-enhancing additive specifically engineered to treat the fireside of furnace/boiler systems against the slagging, fouling, bed agglomeration and corrosion that occurs as a result of burning fuels high in volatile alkalis such as agro-waste, biomass, coal, MSW, pellets and wood.

With increasingly restrictive emission regulations and fluctuating fuel prices, energy producers have to make operational changes such as burning non-design, opportunity fuels. While these opportunity fuels are lower cost, they can be difficult to burn. The slagging, fouling and corrosion that result can increase maintenance costs, safety risks and decrease boiler availability.

Our Aurora product range significantly reduces deposits and can decrease maintenance costs to allow power plants to burn lower quality, cheaper fuels.

The benefits of using our Aurora range include reduced maintenance costs, increased boiler availability, improved safety, lower heat rates and increased fuel flexibility. Our Aurora range is suitable for fuel mixes including agro-waste, coal, meat and bone meal, municipal solid waste, peat, pellets, pet coke, poultry litter and wood waste.

Key benefits

Increased boiler availability – extended time between outages or eliminate them completely, with fewer necessary repairs during planned outages.

Increased fuel flexibility – tolerance of fuel quality variations and potential to burn non-conventional fuels.

Reduced maintenance costs – decreased need for repair or replacement of equipment from erosion, corrosion, or damage from falling slag.

Catalogs

No catalogs are available for this product.

See all of Imerys Ceramics ‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.