Oil additive CynerSorb®

Add to favorites

Compare this product

Characteristics

- Applications

- oil

Description

Our CynerSorb range is a two-in-one replacement additive that delivers absorption and filtration functions in edible oil refining.

Less waste and efficient filtration for edible oils

Our CynerSorb range is a surface-engineered diatomite adsorbent designed to replace silica gels and magnesium silicates in edible oil refining, simplifying the process and reducing spent filter cake and oil loss.

Increases filtration capacity

Reduces oil losses

Reduces bleaching earth dosing rates

Lowers refining costs

Reduces spent filter cake

Two-in-one solution

Edible oils often contain soaps or phospholipids, glycerol and trace metals that need to be removed as part of the refining process. Typically this is done during a filtration stage via the addition of a synthetic amorphous silica gel or a magnesium silicate.

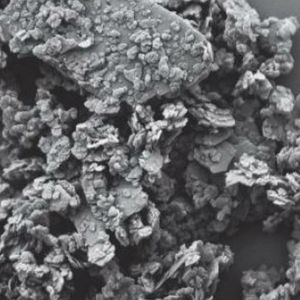

Silica gels and magnesium silicates have excellent adsorption characteristics but are very poor filter aids causing premature filter blockage and reduced refining capacity. Often, a diatomite filter aid is added to compensate for this and to keep the filter bed “open”. While this achieves the required increase in filtration capacity, it also adds process complexity and results in additional spent filter cake – and associated oil loss.

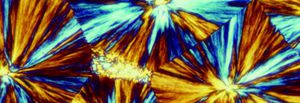

Our CynerSorb range uses a diatomite filter aid base, meaning it has all the filtration characteristics of a diatomite. However, our engineers have successfully surface-engineered the individual diatomite particles so they also provide the necessary adsorption functionality.

As a result, CynerSorb diatomite can be used as a two-in-one solution, fulfilling both the adsorption and filtration functions.

Catalogs

CynerSorb®

4 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.