- Products

- Imerys Ceramics

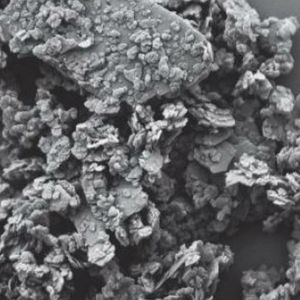

Talc powder Crys-Talc®

Add to favorites

Compare this product

Characteristics

- Material

- talc

Description

You already know that talcs improve flexural modulus combined with excellent dimensional stability and good stiffness/impact balance in plastics. Now see what Crys-Talc can do…

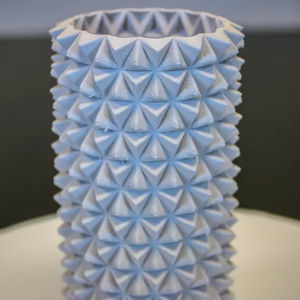

The nuclear option

Crys-Talc is a new, very bright, cost-effective and highly efficient polymer nucleation talc* that improves rigidity and impact resistance, increases injection-moulding and extrusion output, and gives excellent mixing behaviour and dispersion properties.

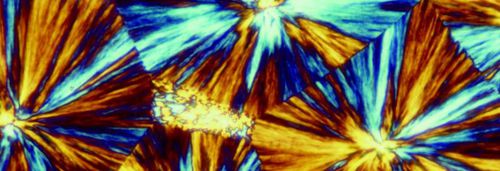

It is a nucleating solution for polymers like polypropylene, polyamides, polyesters and other semi-crystalline polymers. When used in polypropylene, Crys-Talc: increases crystallisation temperature and kinetics; increases injection-moulding and extrusion output by 10-15%; and improves stiffness, strength and Izod impact performance. Use it at higher addition rates and Crys-Talc® acts as a reinforcing agent, improving stiffness, impact resistance and heat distortion temperature.

When used in polyamides, Crys-Talc can significantly increase crystallisation temperature compared to unfilled PA6 or PA6 filled with other minerals. This allows the polymer melt to solidify faster, improves the throughput of industrial processes and reduces injection-moulding cycle times.

Catalogs

No catalogs are available for this product.

See all of Imerys Ceramics ‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.