- Electricity - Electronics

- Switch and Relay

- Protection system

- IMI Critical Engineering

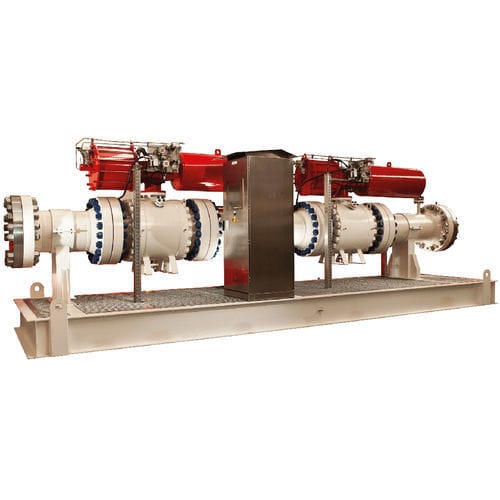

Protection system HIPPS

Add to favorites

Compare this product

Description

HIPPS (also referred to as HIPS) systems are a series of components, specifically engineered to isolate the source of dangerous high pressure instead of relieving the excess flow, in the case of an overpressure event. HIPPS is an independent and reliable Safety Instrumented System that is designed with high integrity as per established ANSI/ISA and IEC standards, in order to equal or exceed the safety performance of conventional safety valves.

Initiators / process sensors- Initiators are either electronic or electromechanical pressure switches or transmitters which measure the process variables (PV) to sense an event. The programmable electronic system receives the signals from the initiators, performs the required logics (voting, diagnostics, and partial stroke test routine) and engages the final elements.

Final elements- The final elements are the physical units that are called upon to isolate the exposure, and are typically fail safe valves, open or closed using spring loaded, hydraulic or pneumatic actuators and solenoids. The final configuration is prescribed by, for the desired fail safe level. The IMI CCI HIPPS design may utilize dual devices in a 1oo2 (one out of two) configuration (two valves in series), where each valve has 1or 2 solenoids (in 1oo2 logic) powered by two independent outputs from the redundant SIL 3 certified Logic Solver.

Safety- As a Safety Instrumentée! System (SIS), HIPPS requires each spécifie applications to be investigated thoroughly. The main metric of the SIS is the safety integrity level (SIL). The SIL represents the necessary risk réduction to obtain the desired tolerable risk, as recognised in a user's risk analysis.

Catalogs

RHPU

4 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.