- Hydraulics - Pneumatics

- Valve

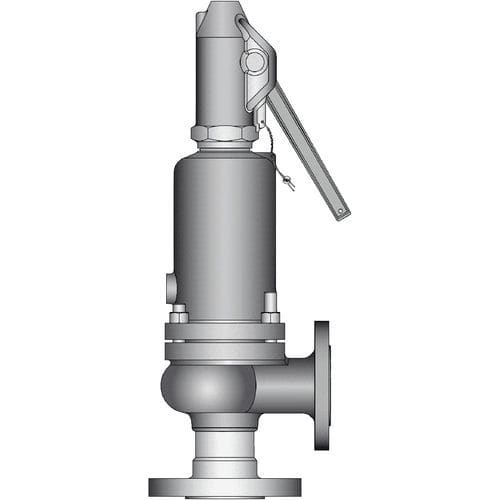

- Steam safety valve

- IMI Critical Engineering

- Products

- Catalogs

- News & Trends

- Exhibitions

Steam safety valve Si 2323DINregulatingthermal

Add to favorites

Compare this product

Characteristics

- Fluid

- steam

- Connexion

- DIN

- Applications

- regulating

- Other characteristics

- thermal

- Controlled pressure

Min.: 63 bar

(913.7 psi)Max.: 400 bar

(5,801.5 psi)- DN

Min.: 15 mm

(0.591 in)Max.: 50 mm

(1.969 in)

Description

Safety valves for pressure relief in accordance to PED and DIN/EN.

Benefits of Si 2323 - Si 2324 - Si

2325

Many of the alternative interstage attemperator systems overlook several or ail of the root causes of failure. Such designs will lead to problems in your plant, it's only a matter of time!

Some of the first signs of trouble start with uncontrolled spraywater flow and leakage. Scheduled inspections often reveal:

Damaged spray nozzles

Cracked attemperator housings

Damaged seals

Cracked steam pipes and boiler tubes

Cracked-broken thermal liners

High pressure drop through the spraywater control portion of the attemperator

High thermal stresses caused by large température différences between the steam and the cooling water

Poor atomization of the cooling water leading to large amounts of unevaporated water in the steam line

Poor installation with short distances to downstream elbows, température sensors, or HRSG re-entry points.

jot cause of most interstage attemperator problems

e traced to four main system-installation parameters:

Damaged spray nozzles

Cracked attemperator housings

Damaged seals

Catalogs

No catalogs are available for this product.

See all of IMI Critical Engineering‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Hyvolution 2025

28-30 Jan 2025 paris (France) Stand 4N20

Related Searches

- Valve

- Hand valve

- Control valve

- Water valve

- Flap valve

- Non-return valve

- Piston actuator valve

- Valve actuator

- Metal non-return valve

- Fluid check valve

- Stainless steel non-return valve

- Safety relief valve

- Spring non-return valve

- Multi-channel manifold

- Water valve

- Pneumatic valve actuator

- Disc check valve

- Steel check valve

- Double-acting valve actuator

- Gas safety relief valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.