- Production Machines

- Other Manufacturing Equipment

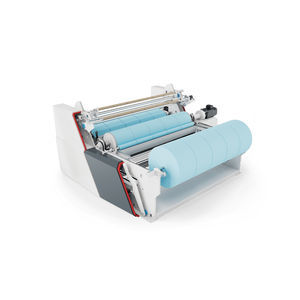

- Paper slitter-rewinder

- IMS TECHNOLOGIES S.p.A.

- Products

- Catalogs

- News & Trends

- Exhibitions

Paper slitter-rewinder AZ 7automatichigh-speedfor the food industry

Add to favorites

Compare this product

Characteristics

- Transformed product

- for paper

- Options

- automatic, high-speed

- Domain

- for packaging, for the food industry

- Working width

1,650 mm

(65 in)- Speed

1,200 m/min

Description

APPLICATION

• Complex material for aseptic packaging for liquid food

The most productive and efficient slitter specifically designed for aseptic packaging material, with individual winding arms and combined surface and axial winding.

Maximum productivity and automation.

The very high productivity is the main characteristic of the AZ7: the winding section is equipped with individual winding arms and the winding system is combined: surface and centre-driven. The machine is specifically designed to cope with all the needs of converters who produce complex materials for liquid food packaging and features all the most sophisticated automation technology required for this domain.

The AZ7 offers top winding quality and very high speed. The typical web width is 1650 mm, the max rewind diameter is 1250 mm and the max unwind diameter can reach up to 2000 mm. The slitting section may include automatic knife positioning and dust suction system. The minimum slit width is 161 mm and the max working speed is 1200 m/min.

The AZ7 offers, as a standard feature, automatic reel unloading system with servo-driven trolleys to transport the reels out of the machine while tilting and conveyor systems are available as options. The unwinder is also foreseen for semi-automatic reel loading.

The AZ7 represents the highest level of performance and automation in the field of aseptic packaging material production: dozens of AZ7’s are installed around the world at all the most important manufacturers of aseptic packing materials

Additional features:

• Complete downstream automation including reel tilting, stamping, labelling and transportation.

VIDEO

Related Searches

- Slitter-rewinder

- Automatic slitter-rewinder

- Automatic winder

- Rewinder-winder

- Manual payout

- Paper slitter-rewinder

- Automatic rewinder-winder

- Plastic film slitter-rewinder

- Motorized winder

- Automatic unwinder

- Paper rewinder-winder

- Embossing unit

- Packaging slitter-rewinder

- Compact slitter-rewinder

- Multi-purpose slitter-rewinder

- Aluminum foil slitter-rewinder

- Modular slitter-rewinder

- High-speed slitter-rewinder

- Fast slitter-rewinder

- Label slitter-rewinder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.