- Production Machines

- Other Manufacturing Equipment

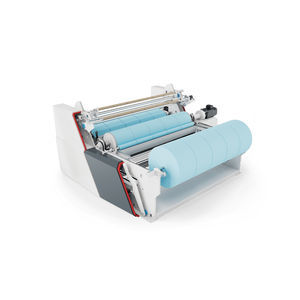

- Label slitter-rewinder

- IMS TECHNOLOGIES S.p.A.

- Products

- Catalogs

- News & Trends

- Exhibitions

Label slitter-rewinder RU 1for aluminum foilfor papermulti-purpose

Add to favorites

Compare this product

Characteristics

- Transformed product

- for paper, multi-purpose, for aluminum foil, for labels

- Options

- automatic, compact

- Domain

- fast

- Working width

1,200 mm

(47 in)- Speed

400 m/min

Description

Paper & Board

Film

Tobacco

Alufoil

APPLICATION

• Hard and soft aluminium foil 8 – 60 µm

• Cigarette and plug wrap papers

• Complex materials for labels

• General purpose thin papers requiring narrow slits

• Silicon-coated paper

• Slitting

• Straw paper

• Tea-bag paper

• Unprinted tipping paper

Multi-purpose slitter rewinder for thin and delicate materials

The RU1 is a compact slitter rewinder with central driven drum and centre-surface winding on two independent expandable or differential shafts. The short distance between slitting and rewinding and the accurate web-tension control system contribute to optimize the rewinding and to maintain a regular and stable web-tension, making this machine suitable to slit and rewind virtually any kind of thin material (paper, film or foil): even the most difficult and tricky materials can be wound with success on the RU1. Furthermore, the compact construction in one single block, makes it very easy and fast to be installed and commissioned: it is really a “plug and play” machine.

Options

• Shafted or shaftless unwinding stand

• Possibility of separate unwinding stand for large diameters

• Slitting section with circular knives or razor blades

• Winding on pneumatically expanding or friction shafts

• Automatic transversal cutting device

• Downstream automation including shaft handling systems and bobbins unloading

VIDEO

Related Searches

- Slitter-rewinder

- Automatic slitter-rewinder

- Automatic winder

- Rewinder-winder

- Manual payout

- Paper slitter-rewinder

- Automatic rewinder-winder

- Plastic film slitter-rewinder

- Motorized winder

- Automatic unwinder

- Paper rewinder-winder

- Embossing unit

- Packaging slitter-rewinder

- Compact slitter-rewinder

- Multi-purpose slitter-rewinder

- Aluminum foil slitter-rewinder

- Modular slitter-rewinder

- High-speed slitter-rewinder

- Fast slitter-rewinder

- Label slitter-rewinder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.