- Production Machines

- Other Manufacturing Equipment

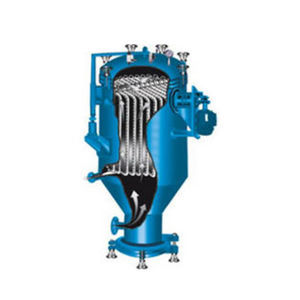

- Batch reactor

- Incalculavel Lda

- Products

- Catalogs

- News & Trends

- Exhibitions

Batch reactor processmodularultrasonic

Add to favorites

Compare this product

Characteristics

- Type

- batch

- Applications

- process

- Configuration

- modular

- Treatment method

- ultrasonic

- Other characteristics

- ATEX

Description

IncBio has conducted extensive R&D in ultrasonic reactor technology, and after a considerably long time spent in testing a variety of feedstocks and processes we have developed our own reactors specifically for industrial processes, on both batch and continuous plants. These ultrasonic reactors can be fully ATEX compliant and can be retrofitted to any operational plant.

By creating molecular cavitation our reactors ensure that whenever a process requires intensive mixing, the medium is homogeneously emulsified and come to a complete reaction, increasing yields dramatically.

Ultrasound is transmitted through a medium via pressure waves by inducing vibrational motion of the molecules which alternately compress and stretch the molecular structure of the medium due to a time-varying pressure.

Therefore, the distances among the molecules vary as the molecules oscillate around their mean position. If the intensity of ultrasound in a liquid is increased, a point is reached at which the intramolecular forces are not able to hold the molecular structure intact.

When the bubbles attain a volume at which they can no longer absorb energy, they collapse violently during a high pressure cycle. This phenomenon is termed cavitation.

The high collapse temperatures and high‐energy particle collisions are responsible for thermal emission. It is estimated that the temperatures inside a collapsing bubble may reach 5,000 K, with pressures in excess of 1000 atm.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.