- Metrology - Laboratory

- Laboratory Equipment

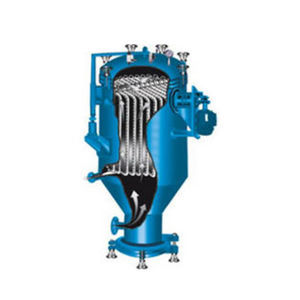

- Vacuum distillation unit

- Incalculavel Lda

- Products

- Catalogs

- News & Trends

- Exhibitions

Not specified distiller vacuumshort path

Add to favorites

Compare this product

Characteristics

- Applications

- not specified

- Other characteristics

- vacuum, short path

Description

When producing Biodiesel from waste products, we cannot always guarantee that the end product will meet the EN14214 specification using our standard equipment. This is not because of our process, it is simply a reality with some low quality feedstock.

But this does not mean that the Biodiesel standard cannot be achieved. With IncBio’s short path wiped film evaporators (WFE), we offer highly efficient and cost effective Biodiesel distillation columns, for plants of any size.

We can ensure that the Biodiesel produced will consistently meet the standards, and most of the times exceed them, meaning that even as the standards get ever stricter, our Biodiesel plants are always able to adapt to the new requirements and be at the forefront of quality Biodiesel production.

Whether the problem is unreacted mono, di and triglycerides, polymerized triglycerides, or failure to meet the ASTM 6751 cold soak filtration test, our Biodiesel distillation columns are certain to solve it.

Working at an extremely high vacuum, they are able to work at lower temperatures than traditional distillation columns, thus reducing energy consumption, and guaranteeing that there is no degradation in the product.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.