- Packing - Handling - Logistics

- Handling and Lifting

- Loading system

- INDEX Drehmaschinen

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

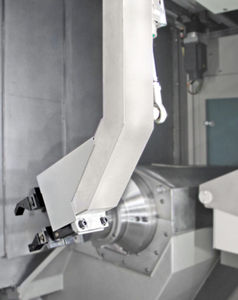

Loading system MBL series

Add to favorites

Compare this product

Description

The bars are drilled in parallel to the main time of the machine, which allows for very quick bar changes

In many cases, higher maximum speeds possible

Setting up the loading side and drilling unit during production

Material feeding on the loading side and setup of the drilling unit during production

Easy access through large doors on the front

Vibration-damping design

Feeding bars in all positions by the NC motor

Bar loading magazine in 2 versions:

- Version 3300: Bar length from 1500 - 3300 mm

- Version 4300: Bar length from 2000 - 4300 mm

Guiding principle

Hydrodynamic guide of bars in oil-flooded channels made of sliding bearing material

The channels are adapted to the bar diameter with plastic reducers (bearing half-shells). Simple clip fasteners facilitate the setup of the bearing half shells.

This results in optimum guidance of the bar stock.

The guiding principle is suitable also for polygon bars.

Bar stock

Round, dia.

mm

5 - 22 (24)

Hexagon, size

mm

5 -19

Bar length - Version 3300

mm

1,00 - 3,300

Bar length - Version 4300

mm

2,000 - 4,300

Bar supply storage

Rack loader, load capacity

mm

700

Bundle loader, Ø 300 mm

kg

max. 2000

General

Speed max.

rpm

10,000

Catalogs

INDEX MS22-8

16 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.