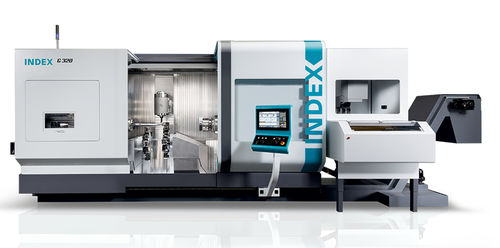

Identical main and counter spindles with spindle clearance Ø 102 mm

3 tool carriers for up to 141 tools

Powerful motor milling spindle with proven Y/B quill kinematics for complex 5-axis milling operations (G320)

Sophisticated work area concept for turning lengths up to 1,400 mm and variable machining options

High thermal and mechanical stability

High acceleration and fast rapid traverse rates up to 50 m/mm

Integrated automation solutions for efficient production

The integrated workpiece handling unit is available as an option. It can be used equally for loading and unloading as well as for the removal of remnants and is designed for parts weighing up to 20 kg and with a diameter of up to 120 mm (shaft) or 200 mm (flange). The handling unit is equipped with 2 or 3 CNC axes that are operated from the machine control. Further individual automation solutions, such as conveyor belts or robot handling with ancillary functions can be integrated on a customer-specific basis.

Complete machining based on a modular system

The modular system in this series offers a wide range of options. Up to 3 tool carriers can be integrated into the work area, and all of them can be equipped with a Y axis. The work area offers ample space to machine any kind of workpiece, accommodating medium-sized parts up to 1,400 mm in length.

The powerful main and counter spindles are designed for bar diameters up to 102 mm and for chuck part diameters of up to 315 mm. Turret steady rests are available for machining long or shafttype parts.

The INDEX G320 features a powerful motor milling spindle capable of simultaneous 5-axis machining.