- Packing - Handling - Logistics

- Packing and Packaging

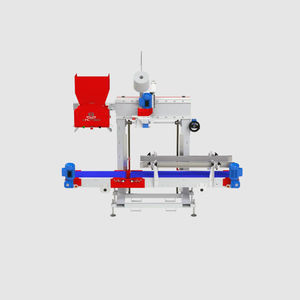

- Vertical bagging machine

- Industrias Technologicas del Pla S.L.U

Vertical bagging machine Flowbag 05flow-packautomaticfor the food industry

Add to favorites

Compare this product

Characteristics

- Type

- vertical

- Technology

- flow-pack

- Operational mode

- automatic

- Application domain

- for the food industry

- Product applications

- for fruit, for vegetables

- Throughput

18 p/min

Description

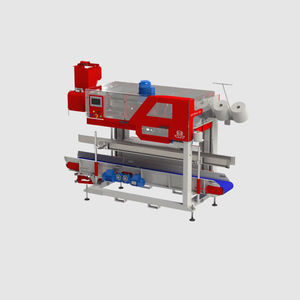

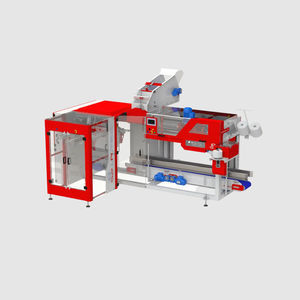

Automatic bagging machine for filling paper bags with high capacity, specially designed for fruit and vegetable products from 2.5 to 15Kg bagged with paper.

In its conception we have based on the automatic placement of these bags, extracting them dosed and sewn by the exit belt.

This bagging machine is controlled by an electronic system capable of giving the necessary orders and adjusting itself to the type of package and its dimensions, so that a great ergonomics and speed of work is achieved.

Its production is totally linked to the product dosing or weighing machine and its mechanical capacity, reaching up to 15 bags/minute.

More information

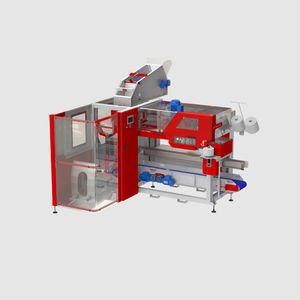

• Proportional opening of the bag: In the displacement of the bag to the mouth, a mechanism is in charge of opening the mouth of the bag during its transport, with the purpose of arriving at this completely open for the later introduction of the shovels that will hold the bag.

• Two-stage inner paddles: The inner paddles are the elements that, in the first stage, allow the bag to be opened internally and, during the second stage, they separate and press the mouth of the bag from the inside against some external rubber bands to hold it and facilitate filling. With the first movement we obtain more reliability and with the second one more opening.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Industrias Technologicas del Pla S.L.U‘s catalogsOther Industrias Technologicas del Pla S.L.U products

BAGGING

Related Searches

- Wrapping machine

- Bagging machine

- Automatic bagging machine

- Automatic wrapping machine

- FFS bagging machine

- Vertical bagging machine

- Stretch film wrapping machine

- Pallet wrapping machine

- Palletizer

- Bagging machine for the food industry

- Turntable wrapping machine

- Automatic palletizer

- Layer palletizer

- Robotic palletizer

- Horizontal wrapping machine

- Wrapping machine with conveyor

- Case palletizer

- Sack palletizer

- Cardboard box palletizer

- Palletizer for the packaging industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.