- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

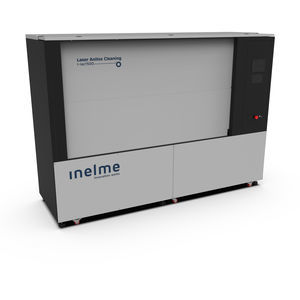

Adhesive mixing unit I-AMX multi-component

Add to favorites

Compare this product

Characteristics

- Options

- adhesive, multi-component

Description

The I-AMX is a two component adhesive mixing equipment available in three versions, without its own tanks and with 30 or 60 liter tanks for glue and catalyst.

BICOMPONENT ADHESIVES MIXER

The system mixes in the desired proportion of adhesive and catalyst taking the necessary amount of each of the components from their corresponding tanks with thermal heating system of 30 or 60 litres (depending on model) by volumetric gear pumps driven by gear motors and controlled by frequency variators.

Each of the two pumps drives a component through the flow meters and through a heated hose is supplied to a mixing nozzle located at the point of application.

The system is prepared to manage two signals from the laminator, a sensor that tells us when it is necessary to perform a dosage (when the level of mixture is low) and a meter-meter signal by which the equipment is able to report the quantity of adhesive dosed per cm2 of rolled product.

ADVANTAGES REGARDING OTHER SIMILAR EQUIPMENT

•Our equipment is more compact, occupies less space.

•It is easy to use and reports the amount of product used per square meter laminated.

•It mixes small quantities in real time of production, there are no remains at the end of the work.

•The dosing system has flow sensors that verify the precision of the mixture. It calibrates itself.

•It can be customised with different adhesive entries (optional).

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.