- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

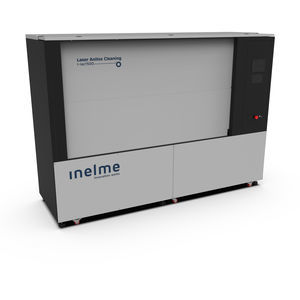

Fiber laser cleaning system I-LAC Portableautomaticopticalanilox roller

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Operational mode

- automatic

- Applications

- optical, anilox roller

- Other characteristics

- portable

Description

The new portable laser anilox cleaning system uses a fibre laser technology to emit a beam through a series of diodes mounted on an optical fibre. The cells of the anilox are completely clean, getting near of the nominal contribution, being able to clean any type of color, base of the ink or adhesive.

During the printing processes, the ink used is deposited at the bottom of the anilox cells and reduces the volume and, consequently, the roll contribution is reduced.

Through laser technology, the laser anilox cleaning system (laser cleaning ceramic anilox) removes ink from the interior of the rolls’s cells, extracting any type of ink, glue or varnish. In this way, the initial volume of the cylinder is recovered 100%, being able to maintain the intensity of the color always constant.

Intuitive software

The laser anilox cleaning system is controlled by a user interface that allows simple and intuitive operation of the machine without the need for additional knowledge.

Easy configuration

Through the touch screen you can adjust the parameters of the anilox in addition to displaying the status of the cleaning at all times.

I-LAC PORTABLE

Minimum diameter of the cylinder: Ø100 mm

Maximum diameter of the cylinder: Ø300 mm

Catalogs

I-LAC Portable

4 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.