- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

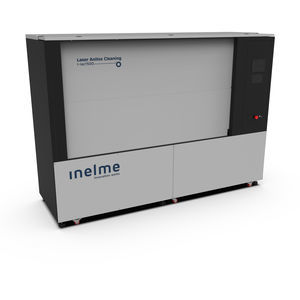

Laser cleaning system I-LAC MULTI CLEANautomaticopticalfor the printing industry

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Operational mode

- automatic

- Applications

- optical, for the printing industry, anilox roller

Description

I-LAC MULTI CLEAN is designed with two or three compartments, depending on the model, specifically for cleaning anilox sleeves. The key feature here is that while one compartment is in the process of cleaning one sleeve, the operator has the option to load another anilox sleeve into a separate compartment to start its cleaning. This optimizes the efficiency of the process by allowing multiple anilox sleeve cleaning tasks to be carried out sequentially, reducing downtime, and increasing overall productivity.

The system effectively cleans the surface of anilox sleeves using laser technology. The process is fast, simple, fully automatic, and leaves the anilox sleeves clean, achieving 100% cell volume without the use of chemicals, bicarbonates, etc. Therefore, the machine only requires electrical power and generates no waste.

Cleaning is carried out with a special diode laser designed to remove foreign elements from the engraved ceramic surface, such as dry ink residues, adhesives, waxes, and silicones that may remain on the surface and inside the cells. All of this without altering or damaging the surface.

It exerts no mechanical action on the ceramic surface, and the expelled dirt is captured by a filter after the ventilation system in the equipment.

Specifications for anilox sleeve cleaning:

Maximum cleaning length of anilox sleeve: 1500 mm

Minimum - Maximum outer diameter of the sleeve: Ø50 - 300 mm

Minimum inner diameter of the sleeve: Ø35 mm

Catalogs

I-LAC MULTI CLEAN

5 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.