- Products

- Catalogs

- News & Trends

- Exhibitions

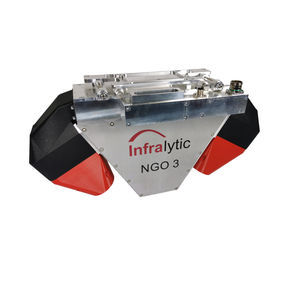

Oil layer thickness sensor NGO3in-line

Add to favorites

Compare this product

Characteristics

- Type

- oil layer

- Other characteristics

- in-line

Description

New fast NGO3 measuring head for contact free oil layer thickness measurement. New materials and more complex components require ever greater precision for the forming process. The lubricating film on steel and aluminum sheets must be adapted to the process. Tool life is to be increased, the number of missing parts in production is reduced and efficiency is increased.

With the new and fast inline oil layer thickness sensor NGO3 you continuously determine the oil layer thickness during the process. You receive the measured values in real time. As a numerical value in g / m², as a graph or as a color carpet, you can immediately see the lubricating film covering with which the material is coated.

You can react directly to under- or over-oiling, flat or partial, and avoid faulty production, process downtimes and increased tool wear.

Statistics are created on the collected data of the production, including the oil layer thickness. This allows conclusions to be drawn as to which oiling is used to ensure the highest level of process reliability, the lowest number of missing parts and the longest tool life. For some subsequent processes e.g. coating or painting measures must be ensured and verified that there is no oil.

All calibrations are interchangeable among the devices of the NG group and can easily be transferred to other measuring devices of the NG series. This applies not only to the handheld devices but also to the inline oil layer thickness sensors NGO3. Calibration transfer from the handheld device to the inline sensor and vice versa.

Traversing continuous oil layer thickness measurement

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.