- Metrology - Laboratory

- Inspection and Monitoring

- Temperature monitoring system

- InfraTec GmbH Infrarotsensorik und Messtechnik

- Products

- Catalogs

- News & Trends

- Exhibitions

Temperature monitoring system SLAG-DETECTprocessmeasurementfor the metallurgical industry

Add to favorites

Compare this product

Characteristics

- Type

- temperature

- Applications

- measurement, process

- Domain

- for the metallurgical industry

- Technology

- infrared camera, visual

- Other characteristics

- real-time, automatic

Description

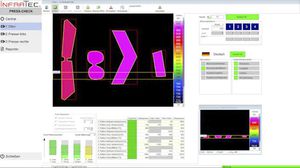

Automatic Slag Detection in Steel Production - SLAG-DETECT

Non-contact slag detection with infrared thermography in steel production

• Clear visual representation of tapping and deslagging processes through excellent image resolution

• Precise distinction between steel and slag

• Function for automated detection of the tapping end

• Comprehensively adjustable data reposting on system PC or data server

• Different variants of interfaces for the integration into process control system

Slag Detection System with LW Infrared Camera for Highest Detection Reliability

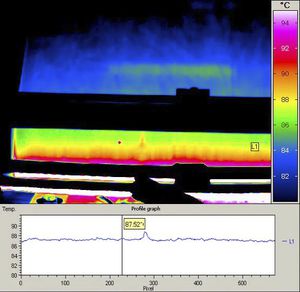

Steel and slag in the process of steel production have different features with regard to radiation physics in the infrared spectral range. Thus, by means of an infrared camera, it is possible to determine without any contact and in real time which of both materials is the current main constituent of the tapping, respectively the deslagging stream coming out of the converter or an electric furnace. For this purpose, the relevant process of steel production is constantly monitored with an infared camera whose sensitivity range involves a long-wave infrared range of (8 ... 12) µm. In this wavelength range appears the highest contrast between steel and slag resulting in the best possible selectivity on material detection.

Other InfraTec GmbH Infrarotsensorik und Messtechnik products

System Solutions

Related Searches

- InfraTec digital camera

- CMOS camera module

- InfraTec industrial camera

- InfraTec infrared camera

- InfraTec monitoring camera

- USB camera module

- Vision processing camera

- InfraTec waterproof camera

- InfraTec detection camera

- InfraTec compact camera

- InfraTec thermal imaging camera

- InfraTec HD camera

- InfraTec GigE camera

- InfraTec rugged video camera

- InfraTec temperature-controlled camera

- InfraTec high-speed camera

- InfraTec CCD camera

- Inspection camera system

- InfraTec IR camera

- InfraTec high-performance camera

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.