- Health - Safety - Environment

- Building Security and Machine Safety

- Condition monitoring system

- InfraTec GmbH Infrarotsensorik und Messtechnik

- Products

- Catalogs

- News & Trends

- Exhibitions

Condition monitoring system alarmfor cranesinfrared

Add to favorites

Compare this product

Characteristics

- Type

- condition

- Applications

- alarm, for cranes

- Technology

- infrared

- Other characteristics

- continuous

Description

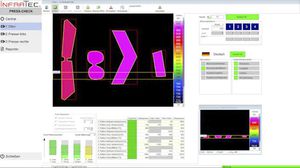

Infrared Thermography for Crane Rope Monitoring in Steelworks

- Fully automatic 24/7 monitoring to detect weak points on crane ropes

- Special tele-optics to detect smallest rope structures over long distances

- Automatic warning and alarm when critical temperatures are reached on the rope

- Precise measured values even under the most adverse environmental conditions

Steel production and processing are accompanied by numerous thermal processes. For quality assurance purposes, the temperatures of the steel itself are recorded and evaluated during production.

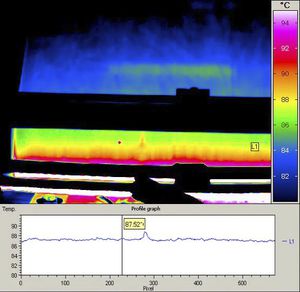

Careful attention must also be paid to the tools and equipment needed for production, including the cranes used to transport the ladles of pig iron. The crane ropes are exposed to great heat when filling the converter (charging). If the ropes become thermally overloaded and simultaneously subjected to strong mechanical stress, they can break, causing molten steel to leak into the production hall. In order to reliably eliminate the likelihood of such a disastrous scenario, a thermographic camera provides a continuous real time temperature measurement and threshold alarming. This allows the reliable early detection of weak points through non-contact monitoring of the temperature of the crane ropes.

Requirements for a thermographic system are very high in this environment. Thermal anomalies must be detected from a great distance despite dust and steam on the very small structures of the rope. Furthermore, the ropes themselves are in front of a hot background.

Other InfraTec GmbH Infrarotsensorik und Messtechnik products

System Solutions

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.