- Metrology - Laboratory

- Inspection and Monitoring

- Temperature monitoring system

- InfraTec GmbH Infrarotsensorik und Messtechnik

- Products

- Catalogs

- News & Trends

- Exhibitions

Weld quality monitoring system WELD-CHECKtemperaturelaser weldingmeasurement

Add to favorites

Compare this product

Characteristics

- Type

- temperature

- Applications

- measurement, laser welding, weld quality

- Domain

- for the automotive industry

- Technology

- infrared camera

- Other characteristics

- automatic

Description

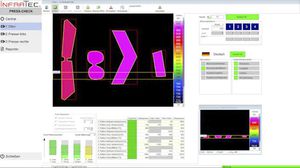

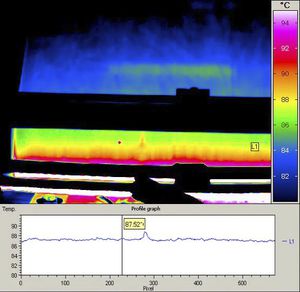

WELD-CHECK is a fully automatic system for non-destructive, contactless examination of welded joints of car bodies and sets new standards for testing accuracy and efficiency.

Quality Control and Weld Inspection with WELD-CHECK

• Universal use through testing of resistance and laser welded joints (resistance welding spots, laser welding seams, RobScan welding seams)

• Increase in efficiency through fully automatic weld testing system with measurement duration of only a few seconds per welding seam or welding spot

• Highest weld testing accuracy through evaluation with special software algorithm

• Detection and classification of various types of defects as deviations in the joining process at an early stage

• Integration into the local quality management by creating test records to be included into databases

Thermography for Fully-Automated Non-Destructive Testing of Car Bodies

Using pulse thermography, the weld inspection system WELD-CHECK enables you a quantitative assessment of the inspected welds. A special software algorithm analyzes the pulse-induced change in temperature in the tested joint and computes, based on its temporal course and geometric spreading, corresponding test results. These results are documented in a test report and provided in a format that can be used in your quality databases. This makes WELD-CHECK the ideal weld test system for automobile body assembly - both as an offline measuring unit as well as for in-line inspection.

Other InfraTec GmbH Infrarotsensorik und Messtechnik products

System Solutions

Related Searches

- InfraTec digital camera

- CMOS camera module

- InfraTec industrial camera

- InfraTec infrared camera

- InfraTec monitoring camera

- USB camera module

- Vision processing camera

- InfraTec waterproof camera

- InfraTec detection camera

- InfraTec compact camera

- InfraTec thermal imaging camera

- InfraTec HD camera

- InfraTec GigE camera

- InfraTec rugged video camera

- InfraTec temperature-controlled camera

- InfraTec high-speed camera

- InfraTec CCD camera

- Inspection camera system

- InfraTec IR camera

- InfraTec high-performance camera

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.