- Metrology - Laboratory

- Inspection and Monitoring

- Temperature monitoring system

- InfraTec GmbH Infrarotsensorik und Messtechnik

- Products

- Catalogs

- News & Trends

- Exhibitions

Temperature monitoring system THSDmeasurementinfrared camera

Add to favorites

Compare this product

Characteristics

- Type

- temperature

- Applications

- measurement

- Technology

- infrared camera

Description

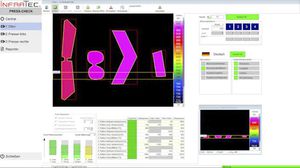

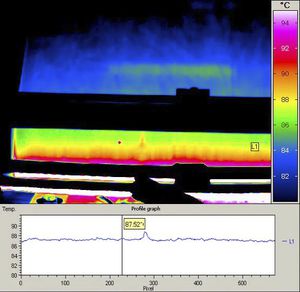

The Torpedo Hot Spot Detection (THSD) system uses the latest infrared technology to monitor the temperature of the torpedo steel structure. Two infrared cameras observe the torpedo cars while they are moving past the inspection site.

The temperature measurements are completely automatic and require no manual interaction. THSD automatically raises the alarm if an adjustable temperature threshold is overrun. This reliably prevents dangerous and loss-making breakouts of liquid iron.

THSD automatically tracks the temperature development of all torpedos in circulation. This allows to maximize the torpedo refractory lifetime without cutback of security and helps to save remarkable costs. THSD comes with highly reliable components in a flexible structure and thus is easily adoptable to the different situations and operational modes in iron and steel plants.

Benefits of the THSD System

• Complete automatic thermographic temperature screening of the outer shell of all torpedos in circulation

• Early detection of hotspots let keep you the close control of the refractory lining of your entire torpedo fleet

• Secure protection against torpedo breakouts saves life, investments and long term operating ability of your shop

• Optimisation of your torpedo fleet deployment improves the quality and saves time and energy

• Prolongation of the torpedo refractory lifetime without cutback of security

• Flexible structure for customised adoption to your operational modes

• Return on investment within less than a year

Other InfraTec GmbH Infrarotsensorik und Messtechnik products

System Solutions

Related Searches

- InfraTec digital camera

- CMOS camera module

- InfraTec industrial camera

- InfraTec infrared camera

- InfraTec monitoring camera

- USB camera module

- Vision processing camera

- InfraTec waterproof camera

- InfraTec detection camera

- InfraTec compact camera

- InfraTec thermal imaging camera

- InfraTec HD camera

- InfraTec GigE camera

- InfraTec rugged video camera

- InfraTec temperature-controlled camera

- InfraTec high-speed camera

- InfraTec CCD camera

- Inspection camera system

- InfraTec IR camera

- InfraTec high-performance camera

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.