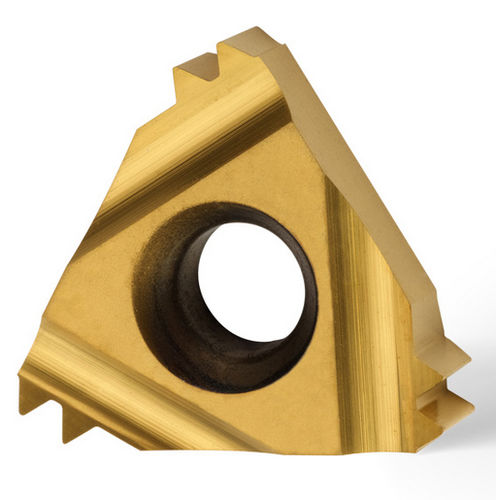

Multi-Tooth Threading Inserts for Decreased Cycle Times

Multi-tooth thread turning inserts are designed to reduce the number of passes required when machining OD and ID threading applications on a lathe. This is achieved by utilizing multiple teeth (2-3) as opposed to standard single point thread turning inserts which utilize only one tooth.

The first tooth is for roughing and semi-finishing which removes the majority of material. The last tooth is designed to finish the thread to the required dimensions according to the thread standard. Multiple teeth allow for a higher metal removal rate, in turn resulting in faster cycle times and overall cost savings.

Features and Benefits

• Increased productivity

• Reduced cycle times

• Longer tool life

• Improved surface finish

• Fewer number of passes required

• Tremendous cost savings

• Larger thread relief required to clear multiple teeth upon exit

• Not recommended for thin-walled applications due to tool pressure caused by multi-tooth inserts

Features and Benefits

Reduces number of passes by 75%

Increased productivity

Reduced cycle times

Extended tool life

Improved surface finish

Larger thread relief required