- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

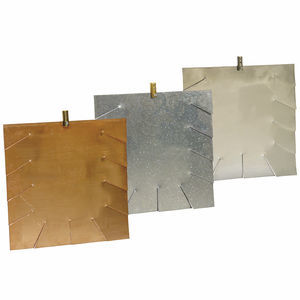

Aluminothermic welding graphite mold 5000 series

Add to favorites

Compare this product

Characteristics

- Applications

- for aluminothermic welding

Description

Aluminothermic welding is a process that takes advantage of the high temperature that develops in the reaction caused by the reduction of copper oxide by aluminum.

The reaction takes place within a graphite mold, where the workpieces have been previously introduced; the metal resulting from the aluminothermic reaction melt flows over them, melting and forming a compact and homogeneous mass.

The reaction is very rapid and therefore the workpieces in the area around the welding point acquires a very significant lower temperature that is obtained using standard procedures, an important factor when it comes to protecting the cable insulation or physical characteristics of the materials to be welded.

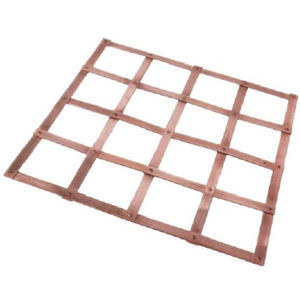

This type of welding may be used to weld copper to copper or copper to steel. Please consult for other materials.

Characteristics

The molds were machined from a block of refractory materials (graphite). Its average duration, in normal use is 70 to 100 welds. A lid protects projections at the time of ignition.

A mold for each type of welding and joining element. Check references of the molds and the list of connections types.

Because of the multitude of connections that can be made, the different materials, conductors and structures that can occur in a system, this catalog only reflects the most common connections (copper-copper and copper-steel). Consult for any other connection.

Catalogs

INGESCO CATALOGUE-EN

50 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.