- Packing - Handling - Logistics

- Packing and Packaging

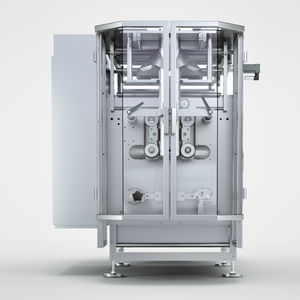

- Vertical bagging machine

- inno-tech Verpackungsmaschinen GmbH

2-way bagging machine REVO SDRverticalVFFSPLC-controlled

Add to favorites

Compare this product

Characteristics

- Type

- vertical

- Technology

- VFFS

- Operational mode

- PLC-controlled

- Other characteristics

- 2-way

- Throughput

Min.: 0 p/min

Max.: 500 p/min

Description

• For all usual bag types

• Low-wear welding and sealing systems

• Heat sealing

• Safely sealed seams thanks to high sealing jaw pressure – cross jaw drive with servo motor, variable opening width (storable in the program), welding and sealing pressure adjustable (storage optional)

• Menu-supported operation via color touch screen, IPC control, memory for 300 programs (optionally up to 1,000), different levels of access (password protected), data backup / transfer via USB, memory card or Ethernet interface optional

• All models with SIEMENS PLC (or B&R)

• Safe film tracking by standard automatic film tracking control

• Easy to clean and easily accessible, no painted parts

• Cabinet made of stainless steel

• Low maintenance, high availability, minimized set-up times

• Synchronization with multi-head weighers without loss of performance

• Intermittent mode for the production of high-quality flat-bottom bags

• Quick-change film roll system with pneumatic clamping shafts

• Vacuum film transport (option)

• Labeler, printer (options)

• Remote maintenance (optional)

• Various sealing profiles

• Euro and round hole perforations available according to customer specification

Catalogs

No catalogs are available for this product.

See all of inno-tech Verpackungsmaschinen GmbH‘s catalogsOther inno-tech Verpackungsmaschinen GmbH products

Product line

Related Searches

- Automatic filler

- Bagging machine

- Liquid filler

- Feeder

- Automatic bagging machine

- FFS bagging machine

- Vertical bagging machine

- Bagging machine for the food industry

- Horizontal bagging machine

- VFFS bagging machine

- Heat sealer

- Bag filler

- Weight filler

- High-speed bagging machine

- HFFS bagging machine

- PLC-controlled bagging machine

- 3-seal bagging machine

- 4-seal bagging machine

- Automatic heat sealer

- Continuous heat sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.