- Packing - Handling - Logistics

- Packing and Packaging

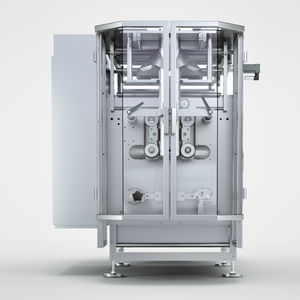

- Continuous heat sealer

- inno-tech Verpackungsmaschinen GmbH

Bag closing heat sealer HVMcontinuousautomatichorizontal

Add to favorites

Compare this product

Characteristics

- Type

- continuous

- Operating mode

- automatic

- Product applications

- for bag closing

- Other characteristics

- horizontal

Description

The combination of a horizontal bag closing machine HVM with integrated REVO bag maker(s) allows a multitude of bag types. Thus, the packaging can be adapted to changing marketing requirements without much effort.

The bags are filled either by the forming tube of the bag maker(s) or directly at the downstream HVM closing line. Thus, the machine can easily be adapted to most different products. Powder products can be packaged almost dust free, and fragile products can be carefully passed directly from the weigher into the waiting prefabricated tubular bag. The number and type of the functional modules are dependent on the customer-specific requirements.

The HVM basically disposes of a vibration module and a sealing module for the bag head. Additional modules are available for head folding by 90°, head folding by 270°,

head labeling, back labeling, hot glue, clip closure (with wire or plastic clip) and various dosing and feeding modules. Servo drives allow very short setup times. The corresponding control parameters are stored in the Industrial PC control with 300 programs (optional up to 1,000) and can be accessed via the color touch screen on the HVM.

Catalogs

Other inno-tech Verpackungsmaschinen GmbH products

Product line

Related Searches

- Automatic filler

- Bagging machine

- Liquid filler

- Feeder

- Automatic bagging machine

- FFS bagging machine

- Vertical bagging machine

- Bagging machine for the food industry

- Horizontal bagging machine

- VFFS bagging machine

- Heat sealer

- Bag filler

- Weight filler

- High-speed bagging machine

- HFFS bagging machine

- PLC-controlled bagging machine

- 3-seal bagging machine

- 4-seal bagging machine

- Automatic heat sealer

- Continuous heat sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.