Leak test bench automaticfor water tanksunderwater

Add to favorites

Compare this product

Characteristics

- Test type

- leak

- Operating mode

- automatic

- Test material

- for water tanks

- Other characteristics

- underwater, for high pressure

Description

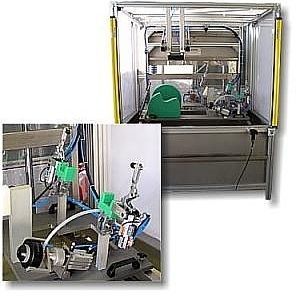

For specific test pieces, particularly hot welded parts, an underwater visual inspection is often the most economical way to test for leaks. Many companies also appreciate our experience when constructing dip tanks, flooding systems and combinations of pressure testing with a leak tester and an underwater visual inspection.

Example I

Underwater visual inspection unit for high pressure cleaning tanks

• Light barrier protection device

• Pneumatic sealing tool with connec ® Quick Connection Systems and floating bearing

• Quick change system for product-specific tool

• Operator confirmation of 'test dwell time' by pressing a manual button

• Ergonomic layout of test piece mounting

• Automatic test piece adaption with part recognition

• Control via Siemens S7/300

Example II

A number of different test pieces are tested for leaks with this underwater visual inspection device. Sealing and clamping tools are therefore designed to be interchanged. The whole mounting is set so that it can be rotated.

• Simple operation, whether manually or automatic

• Ergonomic design

• Simple and functional design

• High degree of processing quality, all parts from corrosive-free materials

• Control with PLC

• Electrical inputs and outputs for clamping devices

Catalogs

No catalogs are available for this product.

See all of innomatec‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.