- Machine-tools

- Machining Center

- 3-axis machining center

- INO Machinery Inc.

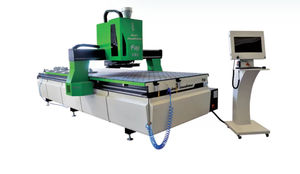

3-axis CNC machining center Ino XX 9900verticalbridgefor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- bridge

- Machined material

- for aluminum

- Spindle mount

- HSK F63

- Associated functions

- cutting

- Applications

- CAD/CAM, for panels

- Other characteristics

- high-speed, compact, high-speed, high-precision

- X travel

8,000 mm

(314.96 in)- Y travel

1,600 mm, 2,100 mm

(62.99 in, 82.68 in)- Z travel

300 mm

(11.81 in)- Rotational speed

Max.: 24,000 rpm

(150,796 rad.min-1)Min.: 0 rpm

(0 rad.min-1)- Power

30 kW

(40.79 hp)- Weight

5,500 kg

(12,125.42 lb)- Overall length

9,570 mm

(376.8 in)- Overall width

2,430 mm

(95.7 in)- Overall height

2,400 mm

(94.5 in)

Description

Machining 2 separate panels like 2 different machines and machining long panels like 6-8 meters with two bridges at the same time with 2 bridges.

In case on of the bridges is broken and stops, the user can work with the machine single bridge and double stations.

It works both as a single machine or 2 different machines.

There are 2 separate bridges but 1 controller.

There are safety sensors on both bridges to prevent from the crash and also on software side there are limits so that the bridges will not meet at the same point.

Profile Machining Software

Our program called CamBOX provides great convenience to the drawing responsibles in the company in the processing of all kinds of panels that are used in the construction industry.

Operations such as machining optimization, tool path optimization, waste piece optimization and determination of tool paths can be done via CamBOX by directly importing the DXF drawings of the panels into the software interface and identifying the different types of machining lines on the panels as different planes.

By entering the sizes of the waste pieces in the production, an optimization list can be created with all waste pieces included if necessary.

Special macros for the composite panel, HPL (Compact Laminate) and Aluminum sheets are already available in the standard version.

New macros can be created according to customer demand.

Not only the macros, but also the buttons, the tool identification, to screen orientation and similar tools can be modified for each customer in case needed.

CamBOX is a great solution for processing any kind of panel dedicated for the construction industry.

VIDEO

Catalogs

No catalogs are available for this product.

See all of INO Machinery Inc.‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Gantry CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- Drilling CNC machining center

- Compact CNC machining center

- 4-axis CNC machining center

- High-speed CNC machining center

- Universal CNC machining center

- Steel CNC machining center

- Composite CNC machining center

- 32 tools CNC machining center

- 20 tools CNC machining center

- Copy router

- End milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.