- Machine-tools

- Machining Center

- 3-axis machining center

- INO Machinery Inc.

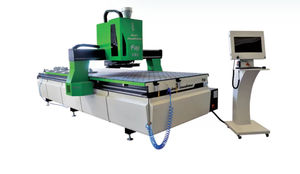

3-axis CNC machining center Ino XT 1640verticalbridgefor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- bridge

- Machined material

- for aluminum, for copper, for composites, acrylic

- Number of tool stations

- 32 tools

- Applications

- CAD/CAM, for panels

- X travel

4,000 mm, 4,500 mm

(157.48 in, 177.17 in)- Y travel

1,600 mm, 2,100 mm

(62.99 in, 82.68 in)- Z travel

300 mm

(11.81 in)- Rotational speed

18,000 rpm

(113,097 rad.min-1)- Power

5.5 kW

(7.48 hp)- Work feed X-axis

1 m/s

(3 ft/s)- Work feed Y-axis

1 m/s

(3 ft/s)- Weight

2,500 kg

(5,511.56 lb)- Overall length

4,900 mm

(192.9 in)- Overall width

2,430 mm

(95.7 in)- Overall height

2,400 mm

(94.5 in)

Description

The CNC Panel Working Machinery specialized for machining aluminium composite panels.

Also called in the market as ACP panels or ACM panels.

The machine first grooves and then cuts the aluminium composite panels by using cutter bits using 2 high speed spindle motors, clamps the panels by vacuuming with a vaccum table and vacuuming pump, extracts the swarf coming out from the panel by a dust extraction system.

All axes are moving on linear guides and moved by servo motors with reducers controlled by a real CNC controller.

The machine can process light alloy materials such as: aluminium composite panels, HPL, aluminium panels up to 20 mm of wall thickness, bakelite, copper, acrylic, plexi-glass and etc.

The machine has a very technologic vacuuming table made from plastic.

The user does not need to isolate the table with gaskets like in the old system.

The vacuuming is isolated inside the vacuuming system under the table and has a very high clamping force.

This is a very new technology only used by ino Machinery.

The vacuuming table is divided into chambers of smaller vacuuming zones.

Each zone is controlled by a 24V pneumatic valve to open and close.

Those valves are controlled by the CNC controller, opened and closed according to the size of the panel.

In ino XT series, the machine decides itself which zone to open and which zone to close, free from the operator control, so that the panel is clamped perfectly on the table and will not move during the processing.

Thanks to the twin-spindle working mentality, there are 2 pieces of spindle motors each 5,5 kW 18.000 rpm, driven by one frequency inverter to adjust the routing speed.

VIDEO

Catalogs

No catalogs are available for this product.

See all of INO Machinery Inc.‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Gantry CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- Drilling CNC machining center

- Compact CNC machining center

- 4-axis CNC machining center

- High-speed CNC machining center

- Universal CNC machining center

- Steel CNC machining center

- Composite CNC machining center

- 32 tools CNC machining center

- 20 tools CNC machining center

- Copy router

- End milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.