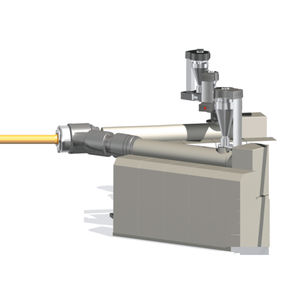

Thickness measuring system diameterflawfor plastic pipes

Add to favorites

Compare this product

Characteristics

- Measured physical value

- thickness, diameter, flaw

- Measured material

- for plastic pipes

- Applications

- control, for extrusion lines

- Other characteristics

- real-time

Description

In ultrasonic measurement, signals of the ultrasonic frequency range are generated, transmitted, received (echoes) and then processed and evaluated. Based on the transit time measurement of the reflecting ultrasonic echoes at the outer and inner pipe wall as well as at the potentially existing boundary surfaces (in case of multilayer pipes), the individual layer thicknesses can be calculated. This requires the coupling medium of water, as well as precise, digitized ultrasonic evaluation electronics. The AUREX ultrasonic systems combine a high accuracy and simple operation for wall thickness and diameter measurement. This means that single-layer and coextruded pipes and tubes can be reliably measured down to a layer thickness of at least 0.05 mm. The interaction of measurement and control ensures overall stabilization of the production process and an efficient production. The early detection of thin and thick sections and the corresponding adjustment at the die leads to a further reduction of production costs. The AUREX systems are available for geometry measurement from 0.5 - 3,000 mm diameter and for 100% wall thickness measurement and flaw detection up to 630 mm diameter.

Advantages:

Detailed product information (wall thickness, diameter, eccentricity, ovality)

Continuous verification of compliance with product specifications

Process automation through control of wall thickness, diameter, weight per meter and mass throughput

Consistent production due to constant wall thickness and centering of tubes and hoses

Material savings of up to 5%

Catalogs

No catalogs are available for this product.

See all of iNOEX GmbH‘s catalogsRelated Searches

- Measuring device

- Measuring machine

- Thickness measuring machine

- Optical measuring machine

- Automatic measuring machine

- Control measuring machine

- Non-contact measuring machine

- Laser measurement system

- Diameter measuring machine

- Geometry measuring device

- Ultrasonic thickness measuring machine

- Handheld thickness gauge

- Thickness measurement system

- Stationary thickness measuring machine

- Automatic calibration thickness gauge

- Real-time measuring machine

- Continuous measuring machine

- Precision thickness measuring machine

- Wall thickness measuring machine

- Online measuring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.